Trend KWJ/OSD True Cut Worktop Jig Out Of Square Device

Klarna 0% finance available on orders over £99 inc. vat

Product Overview

Manufacturer: Trend

-

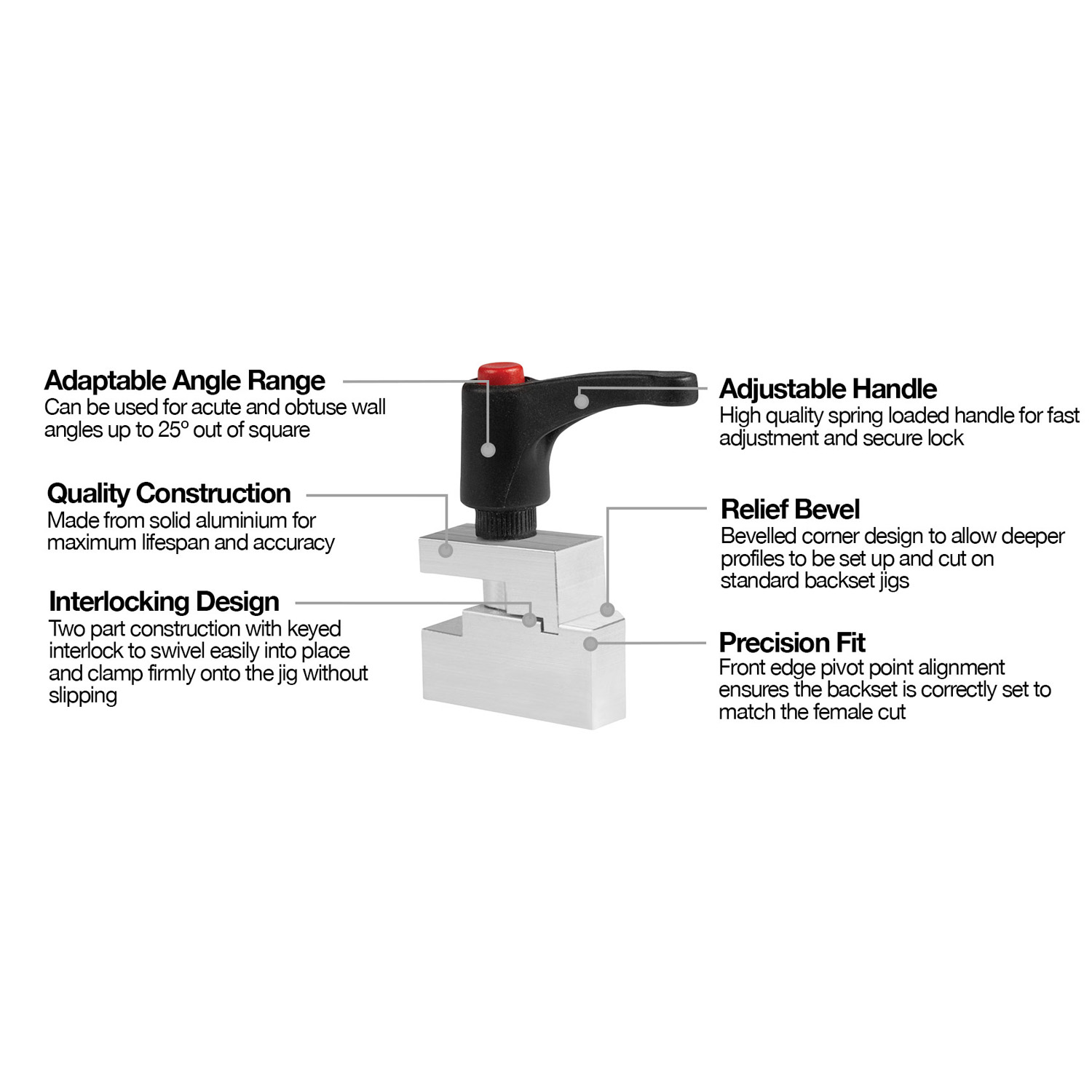

Trend KWJ/OSD Worktop True Cut Kitchen Worktop Jig Out Of Square Device is a worktop jig accessory for making fast, accurate angled worktop joints to accommodate out of square walls.

Read more

Features:

Flexible and adaptable angle range for acute and obtuse wall angles, up to 25 degrees out of square.

Can be used with most worktop jigs up to 12mm thick, including the Trend KWJ750P, KWJ900P, KWJ700, KWJ700S, KWJ900.

Very easy to set up for fast alignment to the worktop edge, ensuring the correct backset position.

Measure, Mark, Clamp, Cut… a simple four-step procedure.

Precise front edge pivot point alignment ensures the backset is correctly set to match the female cut.

Multi-profile is compatible with any worktop edge profile from the square edge to full bullnose.

Made from solid aluminium for maximum lifespan and accuracy.

Two-part interlocking components with keyed interlock to swivel easily into place and clamp firmly onto the jig without slipping.

High quality adjustable spring-loaded handle for fast adjustment and secure lock.

Kitchen fitters will testify that it’s a rarity to find a truly square corner when fitting worktops. Trying to get the corner joints aligned is difficult and time consuming, requiring numerous steps involving complex measuring, marking out and setting bevels, plus constant checking before committing to making a cut. Designed to fit most worktops up to 12mm thick, the Trend KWJ/OSD True Cut Worktop Jig Out Of Square Device is the accessory every kitchen fitter has been waiting for. It can be used with any edge profile so it will meet all current worktop trends including Square Edge, Small Radius, Post Form and Bullnose. The Trend True Cut removes all of the issues and worries of inaccurate measurements and laborious setting up with a fast, simple, and accurate setup.

The Trend KWJ/OSD ensures the worktop jig sits at the correct angle and position to match the angle discrepancy, by constantly retaining the correct backset when cutting the male part of the joint. Once it has been set in position, the True Cut acts as a front edge pivot point that accounts for any acute or obtuse angle discrepancy up to 25° – set with a simple Measure, Mark, Clamp and Cut procedure to make the joint. Manufactured from high quality solid aluminium, the Trend KWJ/OSD True Cut has an interlocking design that allows it to swivel onto the jig for fast positioning so that once set, the interlock engages to prevent slippage, with a spring-loaded lever handle locking it firmly to the worktop jig.

You might also be interested in...

-

Spend £30+vat get a FREE GIFT

Trend GB/US/30 30mm Template Guide for Milwaukee M18FR12

£9.14 exc. VAT£10.97 inc. VAT -

Spend £30+vat get a FREE GIFT

Trend KWJ700/PRO 700mm Pro Worktop Jig Kit

£169.13 exc. VAT£202.96 inc. VAT -

Spend £30+vat get a FREE GIFT

Trend H/JIG/C Two-Part Skeleton Contractor Hinge Jig Kit

£203.98 exc. VAT£244.78 inc. VAT