-

Mirka Goldflex 115 x 125mm Soft Foam Roll for Wood & Paints

£34.93 exc. VAT£41.92 inc. VAT -

Extra Savings on Milwaukee

Milwaukee Bandfile Sander Belts – Pack of 10

£12.95 – £15.83 exc. VAT£15.54 – £19.00 inc. VAT -

3M™ 982C 115mm Cubitron II Premium Fibre Sanding Disc M Stee

£56.87 – £58.35 exc. VAT£68.24 – £70.02 inc. VAT -

3M™ 982C 125mm Cubitron II Premium Fibre Sanding Disc

£49.03 – £53.95 exc. VAT£58.84 – £64.74 inc. VAT -

Save 40% on Maxitek

SpeedGrit XGD High Performance Steel Grinding Discs

£12.30 – £15.66 exc. VAT£14.76 – £18.79 inc. VAT -

Mirka Abranet Ace 81 x 133mm Sanding Sheets – Boxes of 50

£20.01 exc. VAT£24.01 inc. VAT -

Save 40% on Maxitek

Speedgrit Contract 125mm Steel & Inox Cutting Discs – Tin 10

£4.61 exc. VAT£5.53 inc. VAT -

Extra Savings on Milwaukee

Milwaukee 76mm Mesh Sanding Sheets for M12FSDR75 – Pack of 1

£13.46 exc. VAT£16.15 inc. VAT -

Crimped Wire Cup Brushes for Angle Grinders

£18.64 – £25.66 exc. VAT£22.37 – £30.79 inc. VAT -

Fein 6-Hole Triangular Sanding Pads for Wood & Metal

£19.60 exc. VAT£23.52 inc. VAT -

3M™ Cubitron™ 3 150mm Cut and Grind Discs 36+

£73.20 – £81.40 exc. VAT£87.84 – £97.68 inc. VAT -

3M™ Cubitron™ 3 125mm 1182C Fibre Sanding Discs Mild Steel

£56.29 – £67.55 exc. VAT£67.55 – £81.06 inc. VAT

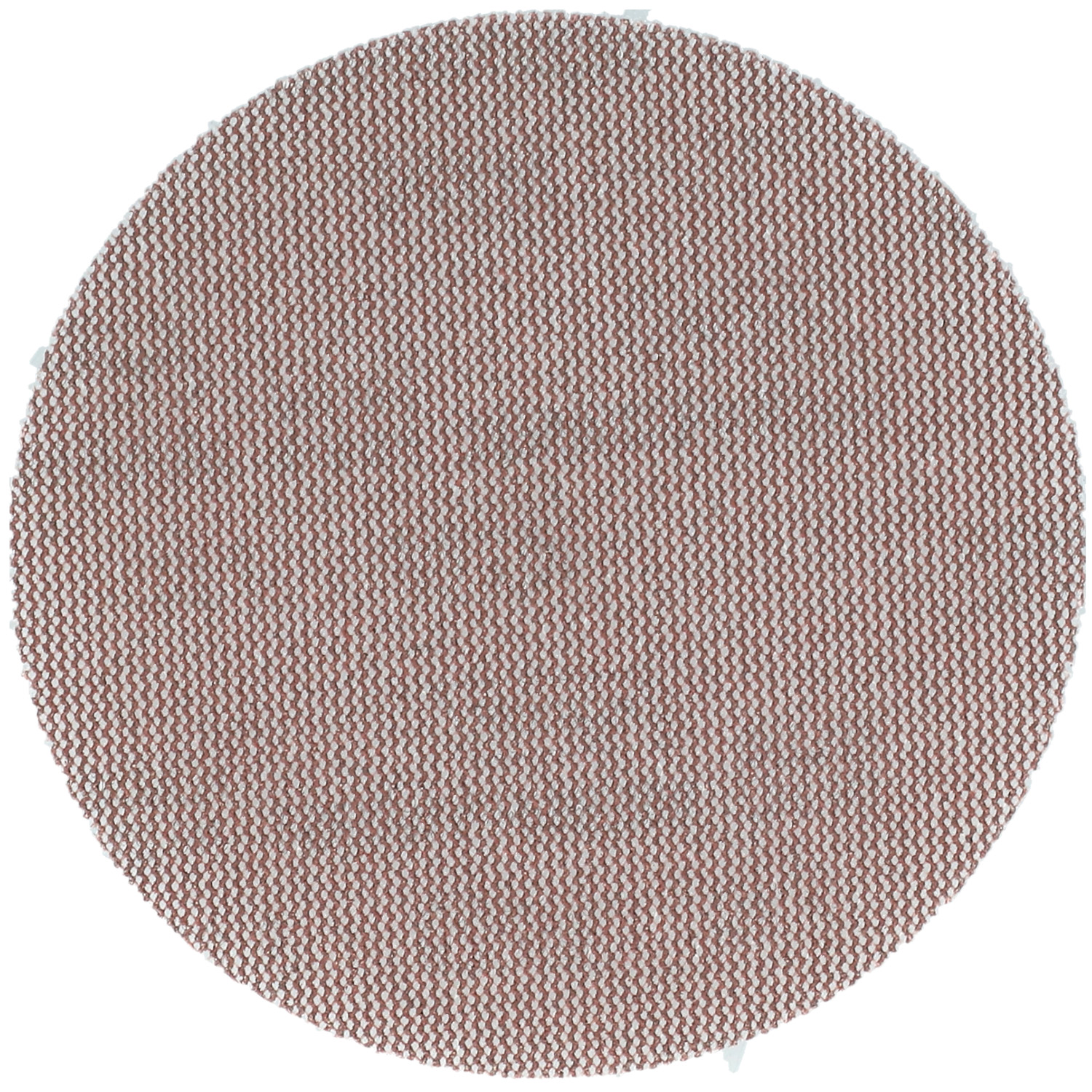

Abrasives

Abrasives are available in a huge range of shapes, sizes and formats and are used to grind and polish many substrates and materials. Commonly referred to as sandpaper from historic manufacturing methods abrasives tend to be separated into two main categories bonded abrasives and coated abrasives. Bonded abrasives are manufactured by bonding the abrasive grain together with resins and reinforcing materials to manufacture products like grinding discs and cutting off wheels. Coated abrasives are manufactured by applying grit to a paper, cloth or polyester backing to make products such as sanding belts, sanding rolls and sanding sheets applications. There are different minerals used in abrasive manufacture with the most popular being aluminium oxide, silicone carbide and ceramic grains; diamond is also used in specialist applications.

A strong factor in deciding what abrasive to select is the material to be sanded. Some substrates are easy to sand but have a tendency to clog the abrasive – such as wood and aluminium. Materials such as stainless steel are more difficult to cut and sand so specialist abrasives that feature in built coolants and grinding aids are normally selected for these applications. The time taken to complete the cutting or grinding application is also a very important consideration as the life of the abrasive can be affected positively or negatively with the speed it makes the cut or the removes the material; in many industries the cost of the abrasive is far outweighed by how quickly the application is completed. In lots of applications the ultimate test of the abrasive is the final finish. The finish attained can differ due to different mineral or grain selection, the pressure applied and the method used on the substrate, for example a linear sanding machine will apply a different finish to a random orbital sander and some hand applied finishes are superior to those where a machine has been used.

Protrade has selected its abrasive partners very carefully utilising each manufacturers area of expertise in their chosen industrial sectors. Our range includes coated abrasives, non-woven abrasives, cutting and grinding discs, wire brushes, wheels and wool. Protrade’s premium range of abrasives include brands such as 3M, Klingspor, Mirka and Maxitek.

Showing 12 of 169 products (page 13 of 15)

Loading filters please wait.