Which are the best Milwaukee Safety Boots for me?

Milwaukee showcased their brand-new range of safety footwear at the Milwaukee European Conference in Stockholm, earlier this year.

This article ‘Which are the best Milwaukee Safety Boots for me?’ is going to look in detail at the range and identify the features and benefits of the various styles that are going to be arriving in the UK very soon. It will cover:

- What are the features and benefits of Milwaukee Safety Footwear?

- What are the differences between Milwaukee FlexTred and Milwaukee ArmourTred?

- What are the differences between the S1PS and S3S safety standards?

- What are the differences between the Milwaukee FlexTred S3S Safety Boots?

- What are the differences between the S3S and S7S safety standards?

- What are the differences between the Milwaukee ArmourTred Safety Boots?

- Verdict: Which are the best Milwaukee Safety Boots for me?

What are the features and benefits of the Milwaukee

Safety Footwear?

The Milwaukee safety footwear is being launched in two different ranges or sub-brands… FlexTred and ArmourTred. On first impression, both ranges look to be incredibly stylish and have the following features for maximum comfort and protection on the jobsite.

ENERGY FOAM heel cushioning system for superior energy return and excellent all-day comfort.

STEP-RELEASE™ heel that allows the wearer to step on the back of the boot with their other foot, for convenient and rapid shoe removal, without damaging the back of the boots.

ROLLCAGE™ heel stabiliser improves stability around the ankle area, even in demanding terrain.

What are the differences between Milwaukee FlexTred and Milwaukee ArmourTred?

So, we’ve identified the major features of the Milwaukee safety footwear range, but what are the fundamental differences between Milwaukee FlexTred and Milwaukee ArmourTred?

Milwaukee FlexTred safety boots are more lightweight and feature a more flexible PU outsole. The benefit of a flexible sole is greater comfort when crouching or kneeling – perfect for many construction trades. They are also completely metal-free, allowing wearers to conveniently pass through any security checkpoints. Milwaukee is initially launching their FlexTred safety footwear in trainer or mid-cut boot, with S1PS and S3S safety standards.

Historical demand and sales for safety footwear have made mid cut safety boots much more popular than trainers, predominantly due to the greater protection around the ankle area plus the VAT-free benefit of buying safety boots as opposed to safety trainers or shoes. For this reason, Protrade are initially launching the much more popular Milwaukee FlexTred Safety Boots with safety standard S3S.

What are the differences between the S1PS and S3S safety standards?

The Milwaukee FlexTred safety footwear is available in S1PS and S3S safety standards. Many construction sites in the UK insist on a minimum footwear safety standard of S3, but what are the major differences between the Milwaukee S1PS and S3S footwear safety standards?

Both S1 and S3 safety shoes and boots have slip-resistant soles, a protective toecap tested to 200 joules, shock-absorbing heels and are also antistatic. The main difference between the two safety standards is that S3 safety footwear has the following additional benefits:

- Water penetration and absorption resistance of the upper material.

- Midsole penetration resistance – also known as ‘nail guard’.

The entry-level Milwaukee S1PS FlexTred safety footwear does have additional midsole protection – which is denoted by the ‘P’ and tested to resist penetration of a 3.0mm diameter nail, which is denoted by the ‘S’ – hence ‘PS’. This metal-free midsole protection matches the Milwaukee S3S FlexTred safety footwear, hence the ‘S’, but the additional water resistance of the S3S enables the safety footwear to be used both internally and externally, as opposed to just internally. Even if you predominantly work inside, getting to and from the workplace or jobsite will almost certainly involve walking through damp areas or puddles, potentially in wet and rainy conditions, so why not keep your feet as dry as possible with a water-resistant and breathable material? With S3 being the minimum safety requirement for safety footwear on the majority of sites and workplaces, our recommendation would be to cover all bases and stick to the Milwaukee S3S options of Milwaukee FlexTred safety footwear.

What are the differences between the Milwaukee FlexTred S3S Safety Boots?

The Milwaukee FlexTred S3S Safety Work Boots are available in two colours… black or beige honey. The beige or honey safety boot has been a popular colour in the UK for a while now, hence Milwaukee including one in their new range. The original ‘yellow boot’ was released by Timberland in 1973. This iconic design ventured across into protective safety footwear by Timberland themselves, as well as CAT and more recently DeWalt. Due to its recognition and style, I can see the Milwaukee FlexTred beige honey boot being popular in the UK, but does it differ from the black version? Looking at the safety conformity of both styles, we can see there is a slight difference.

FlexTred Black S3S: EN ISO 20345:2022 S3S ESD SC FO SR

FlexTred Beige Honey S3S: EN ISO 20345:2022 S3S ESD FO SR

Both styles are tested to the latest EN ISO 20345:2022 safety requirements for commercial use, achieving S3S standard. The letters that follow S3S also denote additional safety features:

ESD stands for Electrostatic Discharge and is a prerequisite for safety footwear in many workplaces. ESD certified boots reduce static generation, and subsequently static shocks.

SC stands for Scuff Cap, and ensures there is abrasion resistance on the impact protection area, or toe cap. A scuff cap will undoubtedly prolong the life of the safety boot, especially if the wearer does a lot of work on their knees, which invariably causes the toe area to wear by rubbing on the floor.

FO stands for Fuel Oil, or the resistance of the outsole to fuel oil and related solvents, thus reducing the detrimental effect on the soles of the footwear.

SR stands for Slip Resistance, a crucial feature of safety footwear. The old slip resistance markings of SRA, SRB and SRC no longer exist, as slip resistance is now considered mandatory for all safety boots and shoes. Safety footwear with the additional SR rating achieve the highest possible slip resistance standard.

So, looking back at the safety conformity of both styles, you can see that the FlexTred Black S3S Safety Boots achieve the additional SC Scuff Cap standard, when compared to the FlexTred Beige Honey S3S Safety Boots. Apart from the obvious colour differentiation, and some may argue the darker shade may get less grubby in time, this is the only other fundamental difference between the two Milwaukee FlexTred S3S safety work boots.

What are the differences between the S3S and S7S safety standards?

The Milwaukee ArmourTred safety footwear is available in S3S and S7S safety standards, so what are the major differences between the Milwaukee S3S and S7S footwear safety standards?

We covered the main features of S3 safety shoes and boots earlier, with slip resistant soles, a protective toecap, shock-absorbing heel, antistatic – plus a water-resistant upper material and midsole penetration resistance. S7 safety footwear also include these features, but what do S7 safety boots offer over and above this?

The single major difference between S3 and S7 standards in safety footwear is that S7 safety footwear contain a waterproof membrane, keeping the wearers feet completely dry when submerged in water – a huge benefit for numerous construction trades including groundworks, bricklaying, fencing and utilities. As explained earlier, the additional ‘S’ for both styles of Milwaukee ArmourTred safety boots, S3S and S7S, means they are both tested to the midsole puncture standard to resist penetration of a 3.0mm diameter nail.

What are the differences between the Milwaukee ArmourTred Safety Boots?

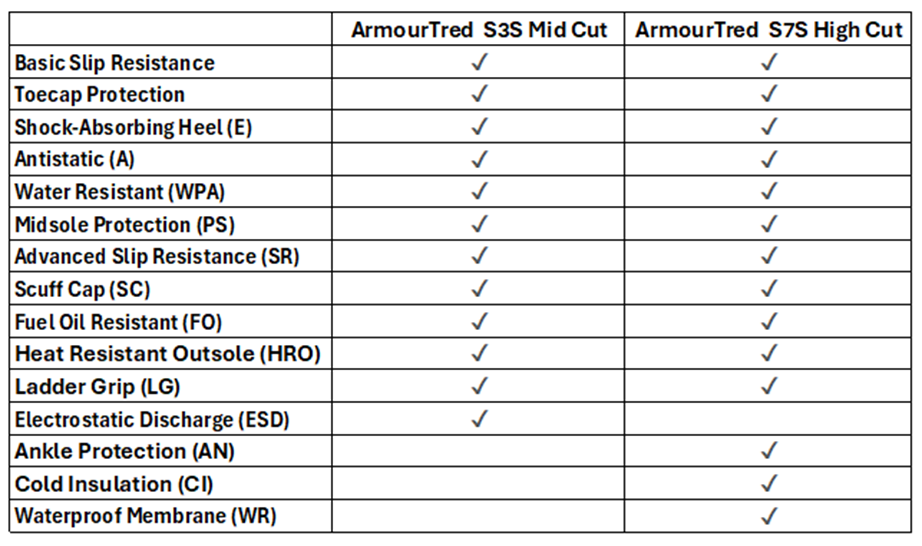

The Milwaukee ArmourTred Safety Work Boots are available in two different ‘cuts’… S3S Mid Cut and S7S High Cut. Milwaukee market a feature called SHOCKSHIELD for both ArmourTred styles, which is a front hammer for added protection, should the wearer accidentally kick a hard object. Apart from the obvious contrasting height of the boots and additional waterproof membrane within the S7S High Cut version, what are the other major differences? Looking at the safety conformity of both styles, we can see there are several differences.

ArmourTred Black S3S Mid Cut: EN ISO 20345:2022 S3S ESD HRO SC FO LG SR

ArmourTred Black S7S High Cut: EN ISO 20345:2022 S7S CI AN HRO SC FO LG SR

Both styles are tested to the latest EN ISO 20345:2022 safety requirements for commercial use, one achieving S3S standard and the other S7S due to its waterproof membrane. The letters that follow S3S and S7S also denote additional safety features:

Both mid cut and high cut ArmourTred safety boots are certified to the additional safety features SC Scuff Cap, FO Fuel Oil Resistance and SR Slip Resistance – all explained earlier in the article. They are both also certified to the following additional safety features:

HRO which stands for Heat Resistant Outsole and means the safety boot’s soles have been tested to withstand significant heat of 300°C, for a minimum of 60 seconds.

LG stands for Ladder Grip, and the sole of the safety boot has a grip area that improves traction when climbing ladders, therefore reducing the risk of falls or slips when working at height.

We’ve identified the common safety features between the two Milwaukee ArmourTred safety boots, but where do they differ?

ESD – out of the two ArmourTred safety boot options, only the S3S Mid Cut Safety Boot is certified ESD for Electrostatic Discharge, so if this factor is an essential safety requirement, the ArmourTred S7S High Cut Safety Boot is not for you.

On the flipside, the ArmourTred S7S High Cut Safety Boot has two additional safety features, that the ArmourTred S3S Mid Cut Safety Boot does not have:

AN certification, which is an Ankle protection standard. It goes without saying that a high cut boot will almost certainly protect the ankle area from impacts more effectively than a mid cut boot, but the higher cut will also reduce the risk of twists as well as protecting the achilles tendon area.

CI stands for Cold Insulation, and this feature alone will make the ArmourTred Black S7S High Cut Safety Boot a massive hit in the UK’s winter months. To achieve this standard, the boots are tested against the cold for 30 minutes at -17°C, and the temperature decrease inside must not exceed 10°C.

The following table is an easy-to-view comparison of the Milwaukee ArmourTred Safety Work Boots:

Verdict: Which are the best Milwaukee Safety Boots for me?

This article has highlighted the various features and benefits of the new range of Milwaukee safety footwear, but which option is best for me? Many of us choose a specific safety shoe or boot based on style… how it looks. We also consider the brand… is it ‘en vogue’? Well, Milwaukee has certainly hit the mark on style and design, and as the fastest growing professional tools and solutions provider in the world, Milwaukee is certainly fashionable! But let’s look past this and determine which Milwaukee safety footwear option is the best choice.

A great deal of research, along with extensive product testing to achieve the various safety standards, has gone into producing this new range of Milwaukee safety footwear. Speaking to the development team personally, they are very proud of what they have created. At the Milwaukee Conference in Stockholm, I noticed that every member of the Milwaukee demonstration team, from all corners of Europe, was sporting a new pair of Milwaukee safety boots. I took it upon myself to personally ask what they thought of them. Without exception, every single person commented on how unbelievably comfortable they were. If you’re wearing your work boots all day, every day, this has to be a hugely important factor.

From a safety perspective, I’d recommend going for protective footwear with a minimum safety standard of S3… you’ll be covered on most job sites. This immediately eliminates the ArmourTred S1PS, but for the very small difference in price between ArmourTred S1PS and ArmourTred S3S, I genuinely can’t see why anyone would consider this as an option – hence Protrade not bringing it into their stocked range. For internal trades, such as joinery, woodworking, flooring, electrical, mechanical, interior fit-out, plumbing and heating – I believe the Milwaukee FlexTred will be more popular, especially if the wearer spends a great deal of time crouching or on their knees. The choice of colour between black and beige honey is a personal preference but bear in mind that the black version has the scuff cap, which will undoubtedly extend the service life of the boots. For this reason, the Milwaukee FlexTred S3S Black Safety Work Boots would be my choice for internal trade applications.

If there’s an element of working at height to your day, regularly climbing up and down ladders, it would be worth considering one of the Milwaukee ArmourTred options – which feature a ladder grip zone on the sole of the boot. Trades including window installation, scaffolders and roofing may find the ArmourTred a better option. If you predominantly work outside in the elements, especially in cold, wet, or damp conditions, the Milwaukee ArmourTred S7S High Cut Safety Work Boots are for you. And if you really want to push the boat out and treat yourself, why not invest in a pair of FlexTred boots for the summer months and ArmourTred boots for the winter months? This way, you’ll certainly have all bases covered!

Milwaukee FlexTred Boots

Expected UK Launch: August 2024

Milwaukee ArmourTred Boots

Expected UK Launch: September 2024

Pre-orders being taken now. All expected UK launch dates shown in this article are estimates provided by Milwaukee UK.

Related Articles

- Why can’t I buy Milwaukee Tools on Amazon or eBay?

- Milwaukee Pipeline – What new Milwaukee Tools launch in 2024?

- Milwaukee 18V Cordless Plunge Saw

- Impact Driver vs Drill: which one do I need?

Joint Managing Director, Protrade

Craig has over 30 years of experience at Protrade, working in various departments including sales, procurement, and marketing, and ultimately becoming Managing Director in 2008. Following the merger of Protrade and Joinery Fit-Out Supplies in 2018, Craig is now the joint MD of the company.