What are the best Velcro sanding discs for wood and other materials?

When it comes to portable sanders, a random orbital sander is by far the most popular. This type of sander comes with a circular Velcro backing pad, which orbits and oscillates in a random pattern – hence the name.

Available in electric, pneumatic, and cordless formats, random orbital sanders remove material quickly and leave an excellent finish. This makes them ideal for nearly every sanding task such as; sanding wood, sanding paint, sanding wooden floors, sanding wooden worktops, sanding solid surfaces, and even sanding metal.

Of course, any random orbit sander is only as good as the accessory used on it. Therefore, it’s really important to choose the best sanding disc if you want to achieve a good surface finish and get the longest life from your abrasive. On the subject of life – let’s not forget your health either. Choosing a Velcro disc that supports dust extraction is also something to seriously consider.

We have referred to the attachment system as ‘Velcro’, although there are other names such as; Grip sanding discs, Hook-and-loop sanding discs, Hookit sanding discs, Stickfit sanding discs, Siafast sanding discs, and Vel sanding discs that are synonymous with abrasive manufacturers.

In this article ‘What are the best Velcro sanding discs for wood and other materials?’ we are going to discuss:

- What sizes of Velcro sanding discs are available?

- What are the differences between paper, film, and net sanding discs?

- What type of grit is used on Velcro sanding discs?

- How does grit size affect surface finish?

- Choosing the correct grit size for your application

- Grit grade application chart

- Velcro disc application and hole pattern compatibility guide

- What are the best Velcro sanding discs for wood and other materials? Summary

What sizes of Velcro sanding discs are available?

Velcro sanding discs are available in 80mm, 90mm, 125mm, 150mm, and 225mm diameters, which can be found below.

For this article, we are going to focus on 5” – 125mm Velcro sanding discs and 6” – 150mm Velcro sanding discs, as these are the most popular.

What are the differences between paper, film, and net sanding discs?

The backing or base layer of a Velcro abrasive is what the grit is bonded to. There are three backing materials used to manufacture Velcro sanding discs.

Paper Backing

Advantages

✅ The most common type of backing used for Velcro sanding discs as it provides a strong, stable base for the grit and is economical to produce.

Disadvantages

❌ Can be prone to creasing and tearing, especially if bumped into upstands.

❌ As paper isn’t perfectly flat, it can compromise the surface finish in very fine sanding applications.

❌ Can only be used dry.

Film Backing

Advantages

✅ Usually reserved for fine finishing applications, film backing is very flexible and resists creasing, it is also highly tear-resistant.

✅ Unlike paper, which is produced by compacting wood pulp, film has a perfectly flat surface which enables the peaks of the abrasive grains to sit evenly on the backing material, providing a more consistent scratch pattern. This makes film discs ideal for paint finishing and pre-polish sanding.

✅ As it’s waterproof, the film can be used for wet sanding.

Disadvantages

❌ More expensive than paper.

❌ Negligible benefit when coarse sanding.

Mesh / Net Backing

Advantages

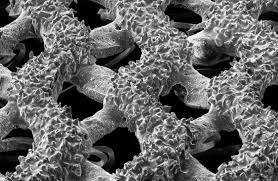

✅ Mesh or net backings have thousands of tiny holes across the entire surface of the disc, offering unrivalled dust extraction.

✅ Less heat build-up and greatly reduced clogging make net abrasives ideal for sanding paint and fillers.

✅ There are no dust extraction holes to align with the backing pad, making disc attachment effortless.

✅ Compatible with all manufacturers backing pads.

Disadvantages

❌ More expensive than paper and film.

❌ Best used for sanding flat surfaces as mesh structures can tear on narrow edges.

❌ Can place extra wear on backing pads, using a protection pad is advised.

What type of grit is used on Velcro sanding discs?

Grit refers to the synthetic grain that is bonded to the backing of the disc, this is what removes material from the surface you are sanding.

The two main types of grit used to manufacture Velcro sanding discs are:

Aluminium oxide

A very hard and tough grain with a wedge-shaped, crystalline structure.

During sanding, pieces of the grain break off which causes the grit to change shape, making it dull in comparison to fresh grain. After prolonged use, cutting speed is reduced and the scratch pattern becomes finer.

Aluminium oxide is the most common type of grain used in the manufacture of abrasives.

Ceramic

The latest in grain technology, ceramic minerals are very hard and take the form of a micro crystalline structure. As ceramic grains wear, tiny fragments of the grit break away, revealing new, sharp edges – thus maintaining cutting speed and a consistent finish throughout the sanding process.

Originally developed for grinding very tough materials such as stainless steel and super alloys, ceramic grit is now being used on high performance Velcro abrasives for sanding wood and composites, offering fast stock removal and very long service life.

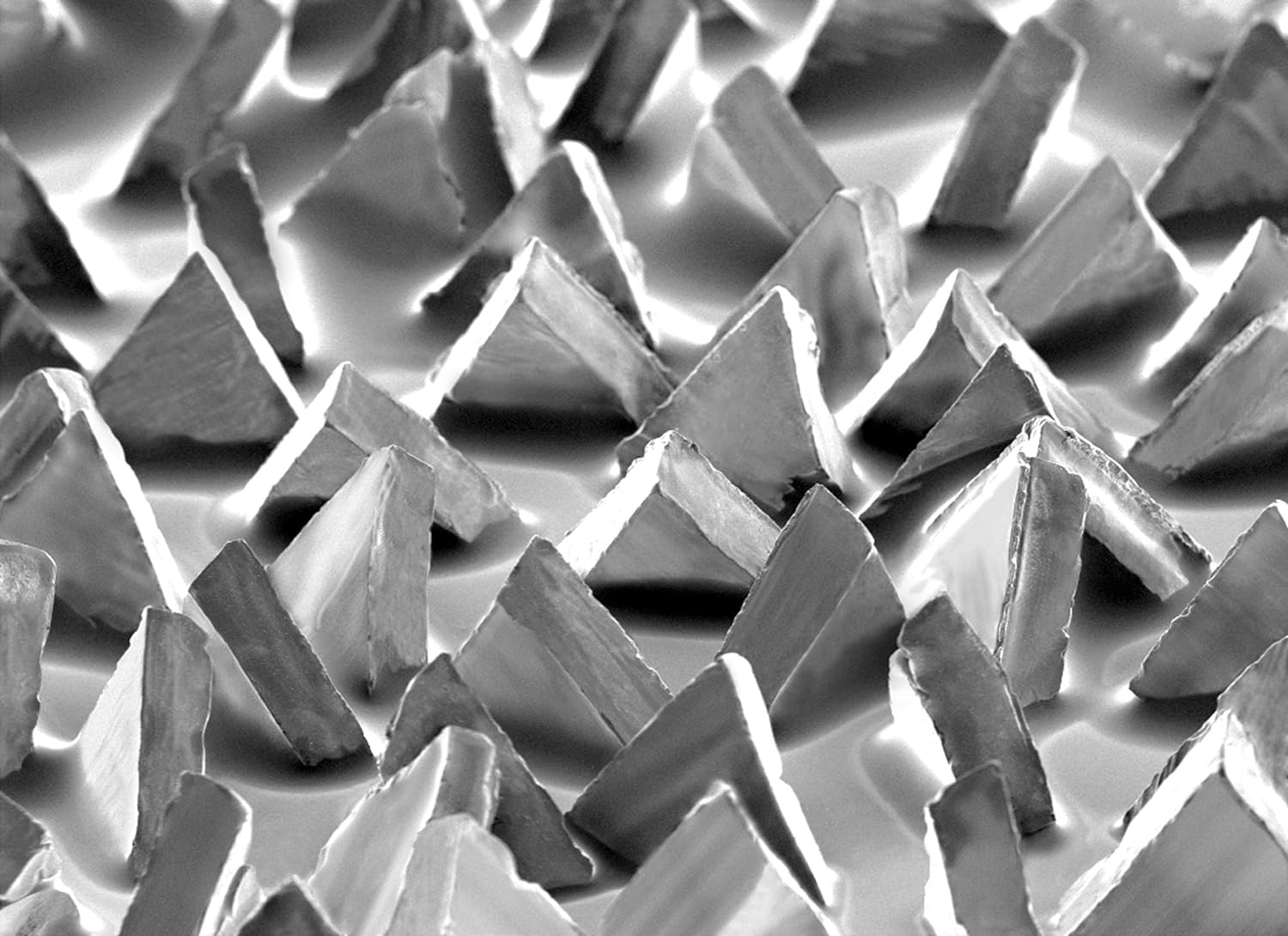

3M has taken ceramic grit one step further by inventing Cubitron Precision Grain – found on the Xtract 710W hook-and-loop abrasive discs.

Perfectly formed, triangular-shaped grains, cut cleaner and faster than traditional abrasives, providing unrivalled stock removal, service life and consistency of finish.

How does grit size affect surface finish?

When the abrasive grit is being manufactured, the many different sizes need to be separated. This is done by using a sieve with a specific mesh size per inch. For example, grains that pass through a sieve with 40 meshes per inch are graded P40.

In terms of grit grading, the higher the number – the finer the abrasive will be.

P40 Extra course → P1000 Super fine.

As sanding is a process of refining scratches, it’s important that you follow a progressive grit sequence in order to achieve a high-quality finish.

The golden rule of sanding is to never skip more than 1 grit.

For example, if you want to end up with a P240 finish, the sanding stage could be P80, P120, P180 and finally P240. This sequence ensures that the subsequent grit can remove the deeper scratches made previously, even though the grades of P100 and P150 have been missed. Jumping from P80 to P180 would skip three grits – P100, P120, and P150, leaving the P180 abrasive incapable of removing the deep scratches of the P80 disc.

Grit grade application chart

Selecting an abrasive with the correct grit size will ensure you get the job done quickly and achieve the desired surface finish.

Our simple grit grade application chart will point you in the right direction.

Grit |

Grade |

Application |

| P40, P60 | Coarse | Removing old paint and coatings.

Flattening rough timber. |

| P80, P100 | Medium |

First stage sanding of hardwoods. Removing saw blade burns. Cutting back filler. Removing loose and flaky paint prior to painting. Final finish for hardwood floors. |

| P120, P150 | Medium/Fine |

First stage sanding of softwoods. Sanding wood before applying primer. |

| P180, P240, P320 | Fine |

Sanding in-between coats of paint, de-nibbing. Flattening raised grain after using waterbased paint. |

| P400, P500 | Extra Fine |

Smoothing top coats. Final preparation before applying finishing oils. |

| P600, P800, P1000 | Super Fine |

Preparation for polishing. Sanding metals and plastics. Final abrasive stage before Scotchbrite application for semi-gloss finish on solid surfaces. |

Hole pattern compatibility guide and velcro disc application

In order to help you choose the correct Velcro disc and ensure that it is compatible with your sander, we have constructed a useful application and compatibility guide, categorising each abrasive material in terms of quality and performance.

Hole Compatibilty Guide |

125mm |

150mm |

|

Good 👍 Mirka Basecut is a paper-backed sanding disc featuring an aluminium oxide grain. Suitable for: all woods, board materials, fillers and paints – making it a cost effective all-rounder. |

N/A |

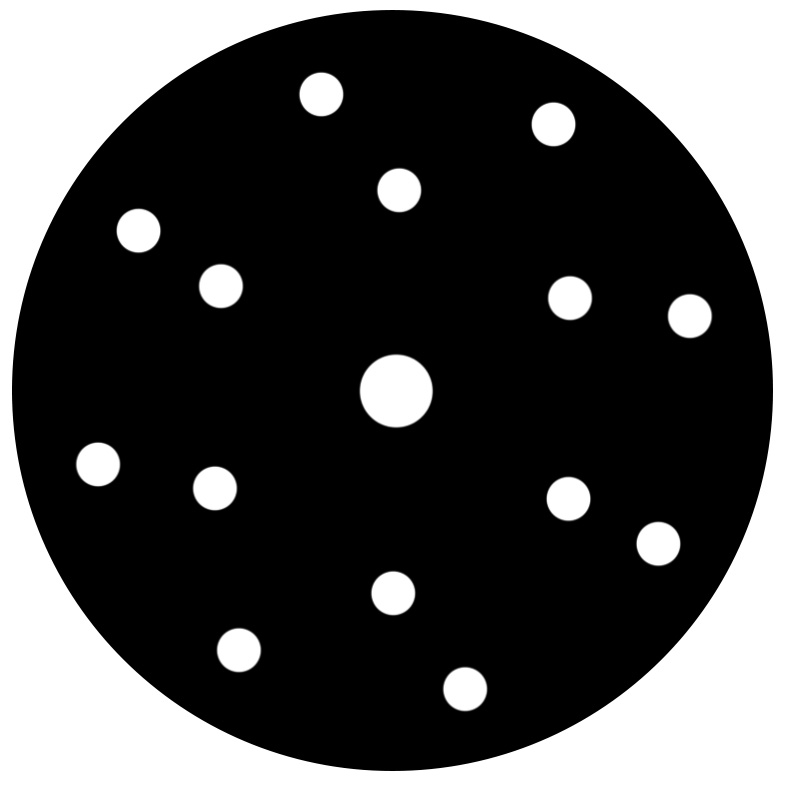

Mirka Basecut 150mm 15 Hole universal pattern fits: Bosch, DeWalt, Makita, Metabo, Mirka. |

|

Better ✅Klingspor PS33 uses special heat tempered aluminium oxide grain for fast cutting and long service life. Suitable for: all woods, MDF, chipboard and composites. Features a stearate coating which reduces clogging when sanding paints and lacquers. |

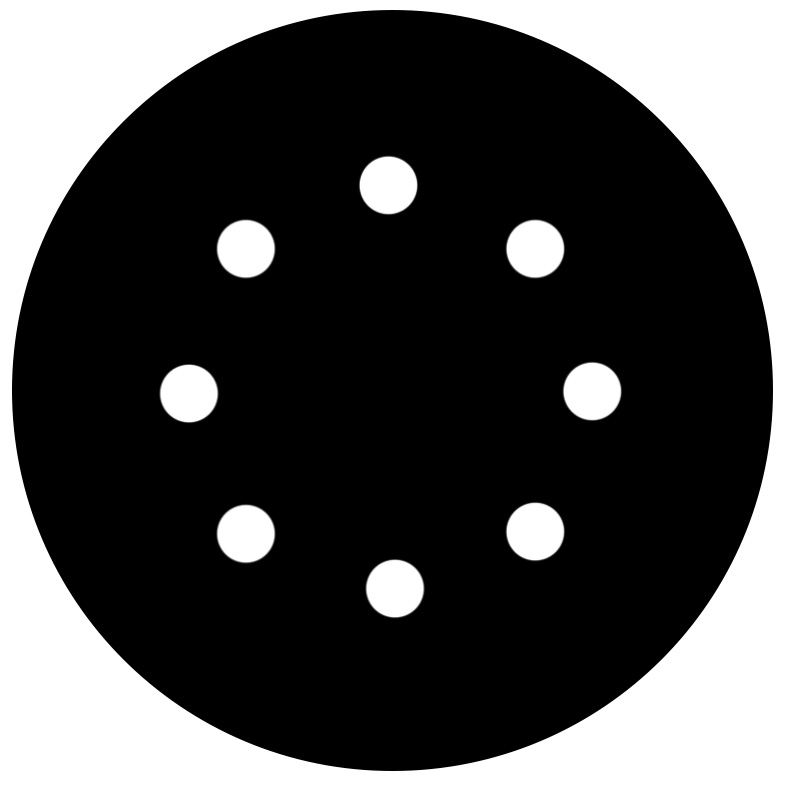

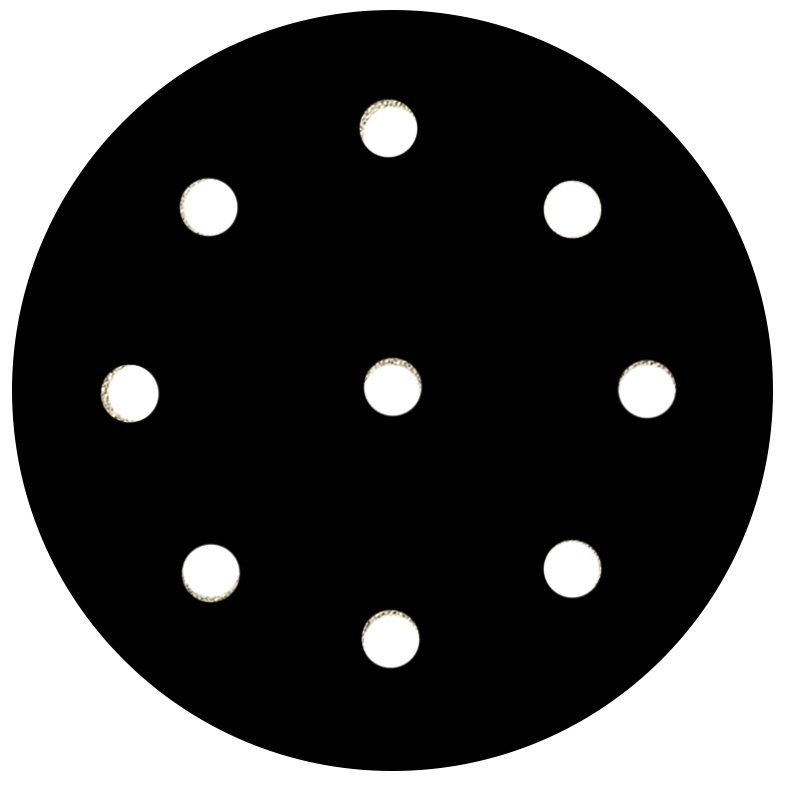

Klingspor PS33`125mm 8 Hole universal pattern fits: Milwaukee, Bosch, Dewalt, Makita, Metabo, Hikoki, Mirka. Klingspor PS33 12mm 9 Hole pattern: specifically for Festool sanders. |

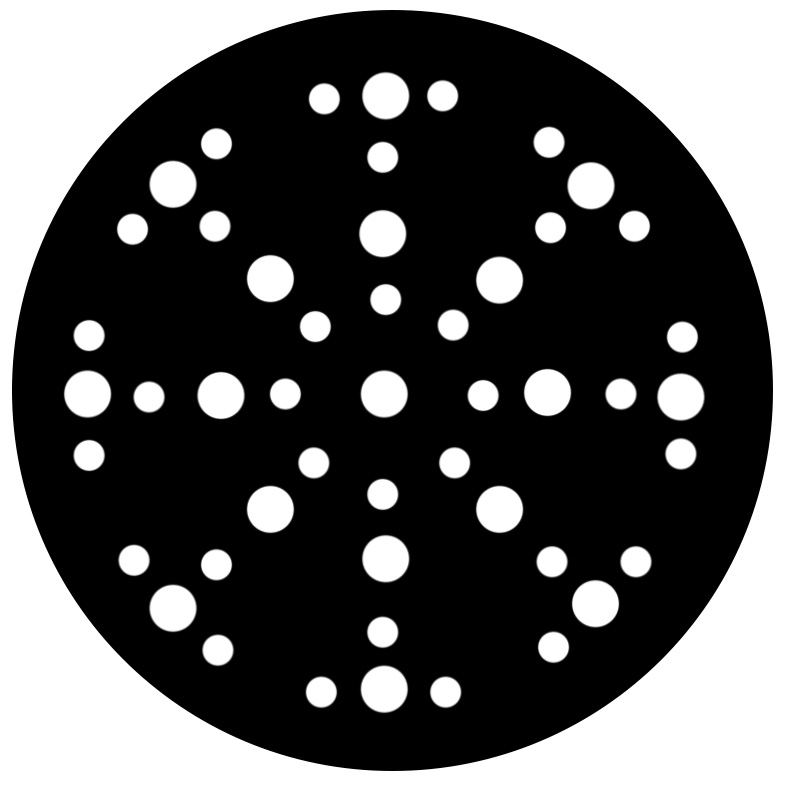

Klingspor PS33 150mm 15 Hole universal pattern fits: Bosch, DeWalt, Makita, Metabo, Hikoki, Mirka. Klingspor PS33 150mm 49 Hole Multi-Jetstream 2 pattern: specifically for Festool sanders. |

|

Best 🏆Klingspor PS/FP 77 is a high performance disc designed for very fast stock removal and outstanding service life. Ideal for production environments. Suitable for: all woods, solid surfaces, composites, wood based materials, paints, lacquers and fillers. |

N/A |

Klingspor PS/FP 77 150mm 49 Hole Multi-Jetstream 2 pattern: specifically for Festool sanders. Klingspor PS/FP 77 150mm 15 Hole universal pattern fits: Bosch, DeWalt, Makita, Metabo, Mirka. |

Application and disc properties |

125mm |

150mm |

|

Good 👍 Mirka Autonet bonds aluminium oxide grit to a net backing, providing excellent dust extraction whilst virtually eliminating clogging. Optimised for sanding paints, fillers and composites, Autonet can also be used for sanding wood, MDF and chipboard, making it a reliable and affordable general purpose net sanding disc. |

N/A |

Mirka Autonet mesh fits all 150mm velcro backing pads. |

|

Better ✅Mirka Abranet Ace has been designed for aggressive, dust free sanding. Utilising ceramic grain, Abranet Ace cuts quickly and remains sharp throughout the sanding process, delivering a consistent surface finish and long service life. Ideal for wood – especially hardwoods, solid surfaces, composites, paints and fillers. |

The Mirka Abranet Ace 125mm fits all 125mm velcro backing pads. |

The Mirka Abranet Ace 150mm fits all 150mm velcro backing pads. |

|

Best 🏆 Xtract™ Cubitron™ II is a revolutionary net abrasive that combines Cubitron™ precision grain with a durable mesh backing. The unique pattern of the abrasive coating prevents grit loss and reduces the chance of tearing. Suitable for use on virtually any material including all woods, MDF, chipboard, plywood, solid surfaces, plasterboard, paint, fillers and metal. |

Xtract™ Cubitron™ II 710W 125mm net abrasives fit all 125mm velcro backing pads. |

Xtract™ Cubitron™ II 710W 150mm abrasives fit all 150mm velcro backing pads. |

What are the best Velcro sanding discs for wood and other materials? Summary

There are so many types of Velcro sanding discs available from numerous brands, choosing the correct type for your application can seem a daunting task. When you add compatibility issues into the mix, what should be a straightforward purchase, becomes stressful and fraught with problems.

In terms of abrasives, we know that this article ‘What are the best Velcro sanding discs for wood and other materials?’ just scratches the surface. However, we hope that it gives you enough valuable information to enable you to select the right abrasive for your application and the correct hole pattern for your sanding machine.

Happy, healthy sanding!