Reducing plastic pollution in the construction industry

Over the past few years, there have been several awareness campaigns launched by government, corporations, and environmental groups to help us understand the damage plastic – in all of its guises – is having on the environment.

With direct influence over our exclusive Maxitek brand, we are continually searching for alternatives to plastics used in packaging.

Earlier this month, we released a product that we hope will go a small way to help the construction industry move away from cartridges in the future – the Sumogrip Foil Pack.

In this article, I analyse why Protrade has decided to take this step as a business as well as what environmental advantages this new product may offer.

What is the most used plastic?

The most ubiquitous plastic in the world today is polyethylene.

The perceived advantages of this plastic are that it’s lightweight. It’s also reasonably strong, easily forms complex shapes, and offers a great deal of resistance when it comes to degradation.

A great example is the now frowned upon, plastic carrier bag.

There are few man-made products weighing in at a feathery five grams that are capable of holding over 12 kilos – that’s over 2,500 times its own weight!

However, the very benefits of this durable material are also its greatest downfall.

It simply lasts too long once it has been assigned to the rubbish bin. The carrier bag, despite its impressive strength to weight credentials, low cost, and convenience, is quite simply an environmental disaster.

No-one really knows exactly how long it takes for plastic-based products to break down, as they haven’t been around long enough to establish fact-based evidence.

The estimate is a wide-spanning 500-1,000 years, so let’s just say an awfully long time.

Products that are readily biodegradable are broken down by being assimilated by microorganisms. In layman’s terms – they are recognised as food and digested. Plastics on the other hand, are not, so the degradation process of being munched by microbes doesn’t take place and hence they remain intact.

How do we reduce plastic waste?

One of the first steps in reducing plastic waste is to try and limit its use.

In October 2015, the UK government made it law for large retailers to charge consumers five pence for each disposable carrier bag to curtail its demand.

Since the charge was introduced, the UK’s main supermarkets have reported a 95% drop in sales of plastic carrier bags. Whilst we’re talking about the vast amount of plastic being disposed of, consider some of the following statistics:

- Humans produce almost 20,000 plastic bottles per second, most of which end up in landfill – the UK alone consuming 38.5 million per day.

- Based on world bank data, the USA generated over 42 million tons of plastic waste in 2016 which, now that waste exported to other countries has been accounted for, makes them the largest generator of plastic waste in the world.

- The UK ranks as the world’s second-worst contributor to plastic waste per capita.

- It is estimated that over two million sealant cartridges are placed into landfill each week!

As a supplier of consumables to the UK Construction industry, we find the figure of two million sealant cartridges going to landfill each week, inconceivable.

Traditional High-Density Polyethylene (HDPE) sealant cartridges are classed as single-use plastics.

What exactly is single-use plastic? Simply put, they are items such as containers, bottles, bags, and drinking straws that are designed to be disposed of immediately after use – destined for our oceans, rivers, or landfill directly after serving their purpose.

Disadvantages of Cartridges

There are two main issues concerning the disposal of sealant cartridges.

Firstly, they are highly unlikely to be recycled as the cartridge is contaminated with traces of the sealant or adhesive inside.

Secondly, the consumed cartridges cannot be compressed or crushed, therefore taking up the same amount of space when buried in the ground, as they did prior to being used.

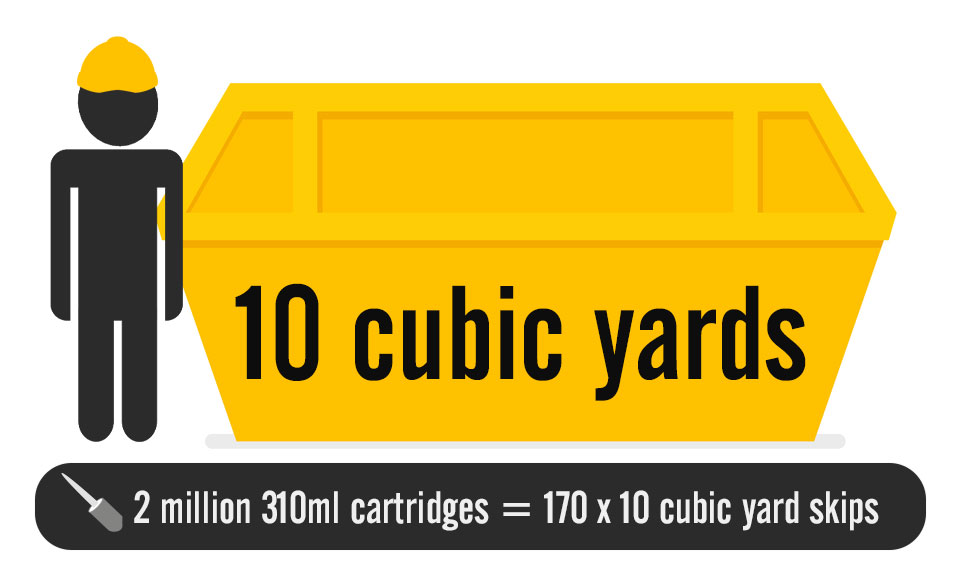

To give you an idea of the space required to dispose of two million empty 310ml plastic cartridges, you need to visualise ONE-HUNDRED AND SEVENTY 10 cubic yard skips a week!

And that’s if the discarded tubes are neatly stacked and don’t include the nozzles either.

What is a Foil Pack?

Foil packs have been around for some time now.

Often described as a sausage pack, due to their resemblance of a large silver sausage, they are manufactured from a flexible aluminium foil skin, which contains the sealant or adhesive material within.

The foil pack is placed into a dedicated foil dispensing gun, which forces the sealant or adhesive out through a re-usable nozzle – as the pack is crushed by a plunger mechanism. The foil dispensing guns look remarkably similar to traditional hand-operated mastic guns.

Foils have always been associated with high volume production environments, such as the caravan and boatbuilding industries.

They have also been predominantly used by specialist sealant applicators, who are often contracted for projects where long uninterrupted beads are applied – literally by the mile.

It’s for this reason that historically, foil packs have only been available in sizes of 600ml.

This cumbersome foil requires an awkwardly long applicator gun – a nightmare if you need to seal inside a shower cubicle or apply in a confined space.

This has made foil packs unpopular with everyday builders, kitchen fitters, and contractors. The simple solution to this problem is a smaller foil pack, which we have decided upon with the Maxitek brand.

What are the benefits of a 400ml Foil Pack?

There are four main benefits to consider here:

- More for the same – Sharing the same dimensions as a 310ml cartridge, a 400ml foil can hold – incredibly –

approximately 35% more product for the same physical size. Compared to 600ml foil packs, the smaller 400ml are much easier to handle.

approximately 35% more product for the same physical size. Compared to 600ml foil packs, the smaller 400ml are much easier to handle. - Economical – Foil packs are often more economical to buy, meaning you get more for your money. The dispensing mechanism also ensures virtually every bit of the sealant or adhesive is used – resulting in little or no waste.

- Waste disposal – Once completely empty, a foil crushes down into a very compact slug – taking up just 5% of the space of a traditional cartridge. That’s a 95% reduction in the volume of waste resulting in significant disposal cost savings.

- Ecological – If we start with the manufacturing process of a foil pack, there are immediate environmental gains to be had. The empty foil packaging starts life as one continuous flat roll, which requires a fraction of the delivery and storage space compared to traditional plastic cartridges. Add to this, the fact that waste disposal is reduced by 95% – fewer vehicles from manufacture through to disposal results in a significant reduction in carbon emissions. Let’s remind ourselves of our endeavour to reduce plastic waste within the construction industry, gradually switching to foil packs will help reduce the alarming weekly consumption figure of two million plastic sealant and adhesive cartridges, and ultimately make strides towards reducing global plastic pollution.

Are they really a viable alternative

Recognising the significant benefits of a smaller foil pack platform, Protrade has established a range of popular sealants and its incredibly versatile Sumogrip Fusion Polymer adhesive – utilising the 400ml size.

Aware that many products used by our customers are still only available in cartridge format, we have also developed the unique Maxitek Duo Flow mastic gun to make life easy, and help with the recruitment of new ‘foil users’.

Features of the Duo Flow gun include:

- It can be used with both foil packs and traditional cartridges

- Fast and tool-free plunger change from foil to the cartridge

- A translucent barrel to allow the applicator to see how much of the foil is remaining

- 12:1 gear ratio to make dispensing sealants and adhesives comfortable and strain-free, significant change considering that most of those two million cartridges applied each week are done so by hand

- Adjustable trigger to accommodate varying hand sizes

- Rotating barrel for comfort in use.

The new foil pack range offers significantly better value for money, without compromising quality or convenience.

Using the earlier example of the carrier bag, we’ve seen behavioural changes in undesirable consumption, by the introduction of a financial penalty.

Therefore, is it feasible to encourage users to try a new, more sustainable alternative, with a value incentive?

Let’s face it, most people are willing to ‘do their bit’ when it comes to saving the planet. If we can also offer commercial benefits, we believe that the adoption of the new 400ml foil pack concept will be embraced by the construction industry.

The verdict

We accept that although manufacturing methods are not yet able to offer sealants and adhesives in rapidly bio-degradable packaging, these silver sausages can help to limit the quantity of plastic being disposed of.

As a supplier to the construction industry, we strongly feel that it is essential to not only offer alternatives, but to continually challenge traditional methods and practises in order to preserve the planet.

Positive environmental changes within a sector that represents over 9% of the entire UK workforce, employing over 3.1 million people, must surely encourage other sectors to consider how they too, can make a difference?

Joint Managing Director, Protrade

Craig has over 30 years of experience at Protrade, working in various departments including sales, procurement, and marketing, and ultimately becoming Managing Director in 2008. Following the merger of Protrade and Joinery Fit-Out Supplies in 2018, Craig is now the joint MD of the company.