The Evolution of Sprayable Contact Adhesives

Contact adhesives have long been used for bonding decorative laminates to substrates such as chipboards, MDF and plywood.

The name ‘contact adhesive’ is derived from how the glue makes the bond. These adhesives rely on both surfaces being coated with the glue and they form a bond upon ‘contact’ with one another. This is a proven and reliable method providing that the rules of application are followed.

Many years ago, when I was a much younger man, I remember watching a cobbler re-stick the sole on my favourite pair o f trainers. I was puzzled how the rubber sole could be attached to the underside of the shoe when the glue applied to both surfaces had been left in the air for nearly twenty minutes and appeared to be dry? It took some adhesives training, about twenty years later, for me to realise that the treacle like liquid was a blend of tacky rubbers and pungent smelling solvent; the latter needing to evaporate and leave behind the actual adhesive. In its dry state, the adhesive was perfectly ready to bond to the opposing material which had also been coated in this treacle like substance.

f trainers. I was puzzled how the rubber sole could be attached to the underside of the shoe when the glue applied to both surfaces had been left in the air for nearly twenty minutes and appeared to be dry? It took some adhesives training, about twenty years later, for me to realise that the treacle like liquid was a blend of tacky rubbers and pungent smelling solvent; the latter needing to evaporate and leave behind the actual adhesive. In its dry state, the adhesive was perfectly ready to bond to the opposing material which had also been coated in this treacle like substance.

When I started to visit joinery shops in the early part of my career, I never ceased to be amazed at the skill it took to apply these traditional, pourable contact adhesives. There was an art in moving the toothed spreader across the board, being careful not to create raised lines in the adhesive. I was also amazed at the skill of being able to scrape up any excess at the end of the application and flicking it off the spreader back into the can. On top of that… how did these guys tolerate the smell?

And then came canister adhesives…

I saw my first canister at a shopfitting company. It wasn’t in use at the time and I asked the workshop foreman what it was. My initial assumption was that it was for spraying paint, as it had a hose and spray gun attached to it. When I was told that it was a new type of contact adhesive I was perplexed as I’d never seen anything like it. The next question was, can you show me how it works? Reaching for a scrap piece of laminate and an offcut of MDF, he proceeded to quickly cover the board in a fine web like pattern. Once the MDF had been sprayed, he got to work on the laminate. Fully expecting to be offered a cup of tea whilst the adhesive ‘flashed off’, I was amazed that after just a couple of minutes he was placing the laminate on top of the board and making a bond that was almost instant. So what did I learn from my first experience of canister adhesives?

- It was easy to apply – even I managed to laminate something

- It was loads faster – compared to using a traditional pourable product

- There was little smell – compared to the traditional adhesive

- It was a sealed system – no more struggling to screw the top on to the tins threads which are usually caked in cured contact adhesive

- We needed to share this incredible product with the rest of our customers

Fast forward a good few years and the concept of canister adhesives is nothing new. Most joiners and fabricators will be using it, or will have certainly used it at some point of their working lives. The concept of a canister system, which is essentially a large aerosol delivering an adhesive product, is widely accepted as the fastest and most convenient way to manufacture laminated boards without presses or large machinery.

Fast forward a good few years and the concept of canister adhesives is nothing new. Most joiners and fabricators will be using it, or will have certainly used it at some point of their working lives. The concept of a canister system, which is essentially a large aerosol delivering an adhesive product, is widely accepted as the fastest and most convenient way to manufacture laminated boards without presses or large machinery.

Surprisingly, the method for manufacturing these products has remained the same over the years. A granular rubber resin type product is dissolved in a solvent to make the liquid adhesive; this liquid is then forced into the can with a propellant which forms the pressurised canister. When the operator pulls the trigger on the spray gun, the contents of the canister is forced through the hose and out of the gun through a tip, which is suited to spraying these materials based on viscosity and the desired pattern. The propellant is discharged into the air, the wet adhesive is left on the board and the solvent present in the wet adhesive quickly evaporates leaving behind a tacky rubber… ready for bonding.

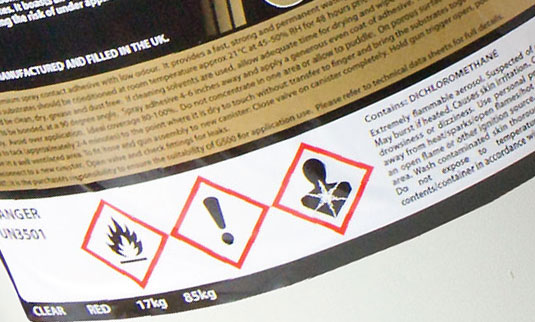

The vast majority of canisters still use a chlorinated solvent in the manufacture of these adhesive systems. Whilst this chemistry has worked very well since the inception of canister adhesives, many users are now concerned about the toxicity of chlorinated solvents – especially when they see concerning warning symbols on the label and then read the hazard statements documented in the MSDS Material Safety Data Sheet.

A typical MSDS for a chlorinated contact adhesive canisters, will often declare the following hazard statements:

- H222 Extremely flammable aerosol.

- H229 Pressurised container: may burst if heated

- H315 Causes skin irritation

- H319 Causes serious eye irritation

- H336 May cause drowsiness or dizziness

- H351 Suspected of causing cancer

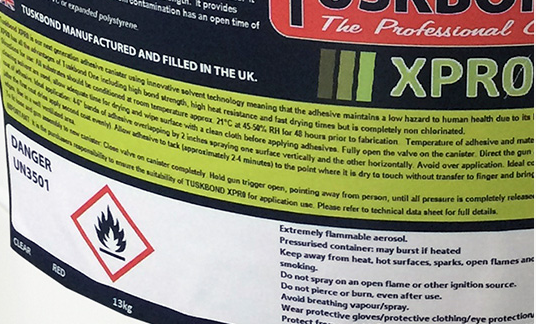

Utilising the latest chemistry, Tuskbond XPRO gives users the same benefits as traditional chlorinated adhesives, but with a solvent that is referred to as being low hazard to human health. The product also has minimal impact on the environment. This proven formulation is therefore obliged to show one warning sign for flammability, and only lists these safety phrases on the MSDS:

- H222 Extremely flammable aerosol.

- H229 Pressurised container: may burst if heated

In terms of performance, applicators can be assured of:

- A fine web spray pattern for a flat even appearance of the bonded laminate

- High solid content for strong dependable bonds

- High heat resistance

- Comparable pricing to chlorinated adhesives – no need to pay much more for a safer solution

- Manufactured, filled and tested in the UK, with full traceability

If you are interested in a safer bonding system, with proven results, please fill in your details below for more information or to arrange a demonstration.

*Required.