Our commitment to a more sustainable future

Construction, for a long time, has held a reputation for being unsustainable, despite the clear and obvious effect it has on everyone.

It provides us with places to live and work. Beyond that, it’s fundamental to delivering beautiful architecture, quality infrastructure, connections, and places to shop and eat. Also, as an employer to over three million people in the U.K, no one can argue that we don’t need the industry.

However, what we can argue is that it needs to do more when it comes to contributing to the topic of sustainability.

How can Construction act?

The construction industry has the technology at its disposal and the capacity to be able to revolutionise the way it works. The sector has approached a junction in the road and we believe that the construction is driving towards a cleaner future.

The world is quite a remarkable place – sometimes contrary to reports – and in order to retain that, there has to be sacrifice, a sacrifice to do the right thing so we can provide longevity for future generations and the planet in itself.

Convenience means people within the industry sometimes take the easy route but it doesn’t necessarily mean that’s the best route. Sustainability isn’t just a buzzword at Protrade. It is something we genuinely believe in and has been part of our ethos since being founded in 1973.

And so, we’re happy to take the longer route. We’re happy to have the tough conversations. And because of our size, it means we’re actually able to adapt far quicker. This is the direction we want to go and we’re hoping many more will follow us, too.

What you can expect from Protrade now and in the future

Let’s start with the products.

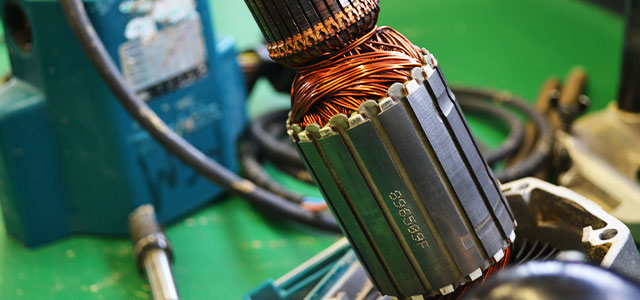

Protrade predominantly sells high-end tools built to endure the rigours of working within a construction environment. Disposable hand and power tools have never and will never be part of our product offering. We’re huge advocates for how a tool can be repaired rather than just tossed into a scrap heap and how our products and brands have the least impact on the planet.

Beyond our products, there’s plenty happening across our East Midlands-based depots and working premises, too. One of the first things our CEO, Matt Bradshaw, introduced upon his joining the company in 2018, was to install low-energy lighting. Although this isn’t unique to us, it is an important small step.

When it comes to the vehicles we operate – our fleet – we’re switching to electric, or as a minimum – hybrid vehicles. Our long-term aim is to get to a position where all of our company vehicles are electric only. To support that, we’ve installed charging stations at our Derby Headquarters and will eventually see these at our depots too.

Inventory management comes into this equation as well.

Stock control and ordering

We’re very particular about how and when we order. Just because you can order something every day of the week, doesn’t mean you should. We have Amazon to thank for that adopted easy come, easy go mentality.

To us, it makes much more sense to place larger orders less frequently – reducing daily orders to weekly or fortnightly and wherever possible, to try and establish a monthly ordering routine. Our Stock Inventory Management System (SIM) which is used by many of our customers, has proved that it’s achievable and it works- reducing packaging, transport, and all associated pollution.

A word specifically on packaging

Speaking of our depots, our customers will have noticed a lot of changes have been made in the packaging we use, starting with how we’re trying to eradicate single-use plastic.

It used to be pretty standard to wrap a product in industrial cling film, but environmentally conscious companies – including Protrade – are exploring how cardboard and corrugated paper can replace it. I’m not talking about radical changes – again, this isn’t ground-breaking – but it’s those small changes that gain momentum and create wider change.

Taking such an approach means we must reconsider how we package and display the products we sell. Naturally, customers are attracted to bright artwork and colourful packaging materials, but we don’t think that should cost the earth or compromise functionality.

It’s often the case that the box costs more than the product inside! Certainly, where our own brand Maxitek is concerned, we choose designs that make it easy for the customer to identify what the product is and use materials that are robust and biodegradable.

Taking such an approach means we have to ditch this former mindset that the products businesses like ours sell need to be attractive – to the extent that it was also fairly common that the packaging those products came in was actually more expensive than the product itself!

Here at Protrade, we’re working on eradicating single-use plastic packaging entirely. We must stress the reference to single-use. For some applications such as tool and storage cases which have a very long service life, a robust and recyclable plastic container can be the most effective and sustainable solution. We actively encourage our customers to ‘buy into’ modular systems that facilitate organised working such as Milwaukee Packout and Festool Systainers.

Our commitment to providing education to our customers

We’ve learned a great deal over the last few years from attending multiple industry events across the world. They were all hugely insightful but we also know that we have a responsibility to continue sharing that education.

An example of that is with our Maxitek Sumogrip and sealants range. As a key product category heavily reliant on single-use plastics, we introduced our own range of foil sausage packs which reduce waste by 95%.

The take-up from customers, initially, was slow. There was a reluctance to switch away from what was previously known. Understandably so.

These products are typically only available in cartridges, but last year, we made the decision to include foils too.

Why not just abolish cartridges? Well, from our perspective, we felt that it was more productive to at least have the opportunity to discuss these new, sustainable products with a customer, rather than giving them no choice whatsoever – something we thought would result in them going elsewhere and resorting back to the single-use plastic cartridges they’ve always used. We definitely don’t want to alienate our customers; dialogue is always the best way to implement change.

That education is a long-term process, but it is one we’re committed to.

The next steps we’re taking

These are just some of the first small steps we’ve taken in our journey to be greener, but we also recognise far more needs to be done. The next step is how we report on that and how we show the value those changes are having within our community.

So, what you can expect from us is that we’re going to be talking about this a lot more and we want you to join us on that journey. This is important – not just to us, our business, or our communities, but for the construction industry as a whole.

On this junction that we’re on, we’re hoping that you will follow us and help in our mission to build a cleaner future within this sector, starting now and for years to come.

Joint Managing Director, Protrade

Des has over 30 years of experience at Protrade, having worked in the capacity of Sales Co-ordinator, Account Manager, and product development, culminating in being appointed Joint Managing Director in 2018.