M Class Dust Extractors: Which are the best?

If you have ever embarked upon a DIY project such as fitting a new kitchen, bathroom or simply re-decorating, a common complaint is the amount of dust it generates. Even though the work may be confined to a single room, those annoying little particles seem to make their way throughout the whole house! Not only is the dust a nuisance in terms of cleaning up, it is also potentially harmful.

Fortunately, the average homeowner only has to undertake these works every few years. But let us now think about the professional joiner, decorator, builder and kitchen fitter who are exposed to these harmful particles every day of their working lives. Limiting exposure to dust in the workplace is important and needs to be taken seriously.

In this article we will explain:

- Why should you use a dust extractor?

- How does a dust extractor work?

- What is a M class dust extractor?

- Why use M class?

- Which M class extractor do I buy?

- Frequently asked questions.

- Summary

Why use dust extraction?

Ignoring the fact that settled dust makes a place look untidy, there are more serious consequences to consider. General household dust alone can trigger allergies, but dust from wood, paint and masonry can lead to serious and even life-threatening illnesses such as cancer and pulmonary fibrosis.

“The average visible dust particle is approximately 10 Microns in size, harmful dust with a grain size of less than 2 microns can remain in the air for 30 minutes making it perfect for inhalation”. Des Duddy Managing Director

Wood dust has long been associated with an elevated risk of lung cancer, but more recently silicosis has been a major focus of the HSE. Silica is a mineral found in many types of masonry such as bricks, concrete, tiles and mortar and it is dispersed into the air when these materials are cut, drilled and broken up. Silicosis is caused by breathing in silica particles which over time, results in irreversible scarring of the lungs making it difficult to breathe and get oxygen into the bloodstream.

‘12,000 lung disease deaths each year estimated to be linked to past exposures at work’ – HSE work related ill health and occupational disease statement’

How does a dust extractor work?

Air pressure!

- When the extractor’s motor is switched on, it turns a fan which removes air from the inside of the container sending it out into the atmosphere by an exhaust outlet, creating a low-pressure region inside.

- The air outside the container is therefore at a higher atmospheric pressure which wants to move to the lower pressure region inside the extractor, taking any dust and contaminants with it.

It sounds very complicated but it’s the same principle as when you use a drinking straw in a glass of water.

Virtually all commercial dust extractors use a dust bag and cartridge filter system to trap dust and filter the incoming air. As air and dust enters the container the first filtration process is via the dust bag, this removes most of the particulates.

Any exceptionally fine particles that permeate through the bag are then filtered out by the main cartridge filter before the clean air is sent back out into the atmosphere. This system is highly effective offering very high levels of filtration and limits the operator to re-exposure when the dust bag needs to be replaced.

Reducing the amount of dust being put into the air is always the best place to start and this can be achieved by connecting ‘on tool’ extraction. This normally means connecting to the dust extraction outlet of a power tool directly but there are accessories from manufacturers like Milwaukee and Festool that allow applications such as drilling to be completed dust free. If extraction at source is simply not possible, particles that have settled will need to be vacuumed up using a suitable extractor that prevents the finest and most harmful dust from being dispersed back into the atmosphere.

What is a M class dust extractor?

The three main classes of dust extraction on the UK market are L, M and H and are determined as below:

L Class – Dust that is considered Low risk such as typical household dust and soil. The filtration system needs to capture at least 99% of dust.

M Class – Dust that is considered Medium risk including; all wood dust, MDF, repair fillers, concrete, cement, plaster, materials containing quartz, latex and oil-based paints. The filtration system needs to capture at least 99.9% of dust.

H Class – Dust that is High risk ad contains carcinogens and pathogens such as asbestos and mould. The filtration system needs to capture at least 99.995% of dust.

When we talk of dust extraction, we often hear about HEPA filters – High Efficiency Particulate Air. Typically, these are H13 and H14 grade which filter to 99.9% and 99.995% respectively.

In the UK there is a legal requirement to use the correct type of extraction equipment during any operation that generates potentially harmful dust. The HSE issue heavy fines for any person or organisation that fails to comply. In order to explain the functions and capabilities of M Class dust Extractors, we need to be able to view them in the context of other classes of extraction.

Why use M Class Dust Extractors?

Most tradespeople will be exposed to dust from materials identified in the M category. Tasks ranging from sanding painted window frames, wall chasing, cutting worktops and floorboards all carry a risk of harmful dust inhalation requiring an M class extractor.

Indeed, the HSE set a minimum requirement of M class when using on tool extraction for controlling construction dust. https://www.hse.gov.uk/pubns/cis69.pdf

It is also important to realise that simply fitting an M-rated filter to an extractor does not make it an M class machine. Although it is essential the filter does meet the M standard the machine and components must be tested as a whole. The extractor is also required to have:

- A filter bag that can be disposed of without causing risk to others – often by way of a seal which caps the entry port.

- An indicator (usually an audible alarm) which alerts the user to a drop in airflow preventing the machine from working efficiently – as the case would be if the bag was full, hose blocked, or filter clogged.

- Clear markings indicating its dust class.

What M Class Extractor do I buy?

Mains power or cordless dust extractor?

Until recently, cordless extractors were limited to performing small cleaning tasks containing low hazard dusts. Certainly, there were no commercial grade, M class extractors readily available.

Advances in Li-Ion battery technology have now made it possible to manufacture cordless M-class extractors that are comparable to mains powered machines.

Without a cable, portability is taken to a new level as you are no longer tethered to a plug socket and your working range is limitless. If dust and cord free working sounds interesting, we recommend these cordless extractors from Festool and Metabo.

Cordless M Class Dust Extractors

Metabo ASR3618 BL 18V-36V Cordless M Class Dust Extractor

When buying any cordless power tool, the battery platform it uses is a major purchasing influence – especially if you already own other brands of cordless tools. Fortunately, Metabo helped to create the Cordless Alliance System (CAS) which allows a single battery pack type to be used across many leading power tool brands including Lamello, Mafell, and Trumpf.

Working from 2 x 18V batteries the Metabo ASR3618 BL offers the same performance as its mains powered siblings.

Key features:

- Cordless Control – A common complaint about cordless extractors is there is usually no way of automatically turning the extractor on by pulling the trigger of the power tool connected to it – something which is catered for by the electrical Auto Take Off feature on a mains tool. This leaves the user having to manually activate it – inconvenient to say the least. Cordless Control turns the extractor on as soon as you start your power tool, what’s better still, is that it works with ANY cordless power tool regardless of brand or battery type.

- Semi-automatic filter cleaning shakes both filters to ensure optimum cleaning performance, promoting efficient and safe working.

- 4 Metre x 35mm hose and floor tool set convert the extractor to a site vacuum for safe clean up at the end of the job.

Protrade’s Verdict: Ideal for cross-compatibility with other tools.

Festool CTMC MIDI 36V M Class Cordless Dust Extractor

Festool has long been regarded as a one of the best portable dust extractor manufacturers on the market. Their entire range of power tools always considers the removal of dust at source and extraction outlets are designed into rather than added on to the tool. This premium power tool manufacturer regards the dust extractor as the foundation of any power tool system, as it not only promotes safe working but also makes for a convenient transport device once other power tools are secured on top of the extractor using Festool systainers.

Key features:

- Uses Bluetooth connectivity to start the extractor automatically, when using other Bluetooth enabled, battery powered Festool tools. Non Festool users can activate the machine using the remote-control switch which attaches to the tool end of the hose.

- Stable, low centre of gravity housing prevents the extractor from toppling over when transported or pulled around the jobsite. Integrated hose storage and the Systainer dock not only keeps accessories neat and tidy (a bugbear of any extractor user) but allows multiple Systainers to be stacked and wheeled around effortlessly.

- Manual filter and bag cleaning keeps the extractor’s air flow rate at an optimum and promotes maximum bag fill. As the filter can be removed without opening the machine up, inspection and replacement is quick and easy.

Protrade’s Verdict: Perfect for keeping the job site tidy if you use the Systainer storage system.

Festool CTMC SYS 36V M Class Cordless Dust Extractor

We have already touched on the quality of Festool extractors, so the major focus of this cord free Festool M Class extractor is portability. Built on the revered Festool Systainer concept, the CTMC SYS extractor can be used on the move via a comfortable shoulder strap and weighs just over 8 kilos – that’s less than your typical aeroplane hand luggage allowance!

Key features:

-

- Easily transported and carried using a shoulder strap. All accessories neatly packed away in the ‘Tote like’ hose holding Systainer which is detachable.

- Bluetooth connectivity and remote-control switch allows automatic start up for existing and non Festool users respectively.

- Stack with all Systainer modules.

Protrade’s Verdict: Our most portable M Class extractor, fantastic when mobility is an important factor.

Milwaukee M Class Cordless Dust Extractor

At the time of writing Milwaukee did not have a UK specification M Class cordless extractor, but we believe that one may be released in the near future. Check here for updates Milwaukee Cordless M Class Dust Extractor Coming Soon – Protrade.

Corded M Class Dust Extractors

For unlimited run time during applications that require continuous dust extraction or workshop based manufacturing, a mains powered corded extractor is likely to be the correct choice for professional users. With numerous mains powered M Class extractors available, we have carefully selected three machines below, which have over time, proven to be reliable and offer excellent performance and functionality.

Nilfisk Attix 33-2M PC M Class Vacuum Dust Extractor

Nilfisk are one of the foremost manufacturers of dust extraction equipment in the world, often manufacturing for other well-known industrial brands. Using years of experience, Nilfisk have developed revolutionary filter cleaning methods whilst focussing on functionality and performance throughout their range of portable dust extractors.

Whilst many manufacturers did not even have an M-Class offer in their extractor line up, Nilfisk launched the 33-2M, which promoted easy connectivity through a versatile tool adaptor and a toolbox fastener attachment which could be used to mount Systainers and L-Boxx cases. High suction performance and a large fill capacity has made the Nilfisk 33-2M one of our most popular M Class dust extractors.

Key features:

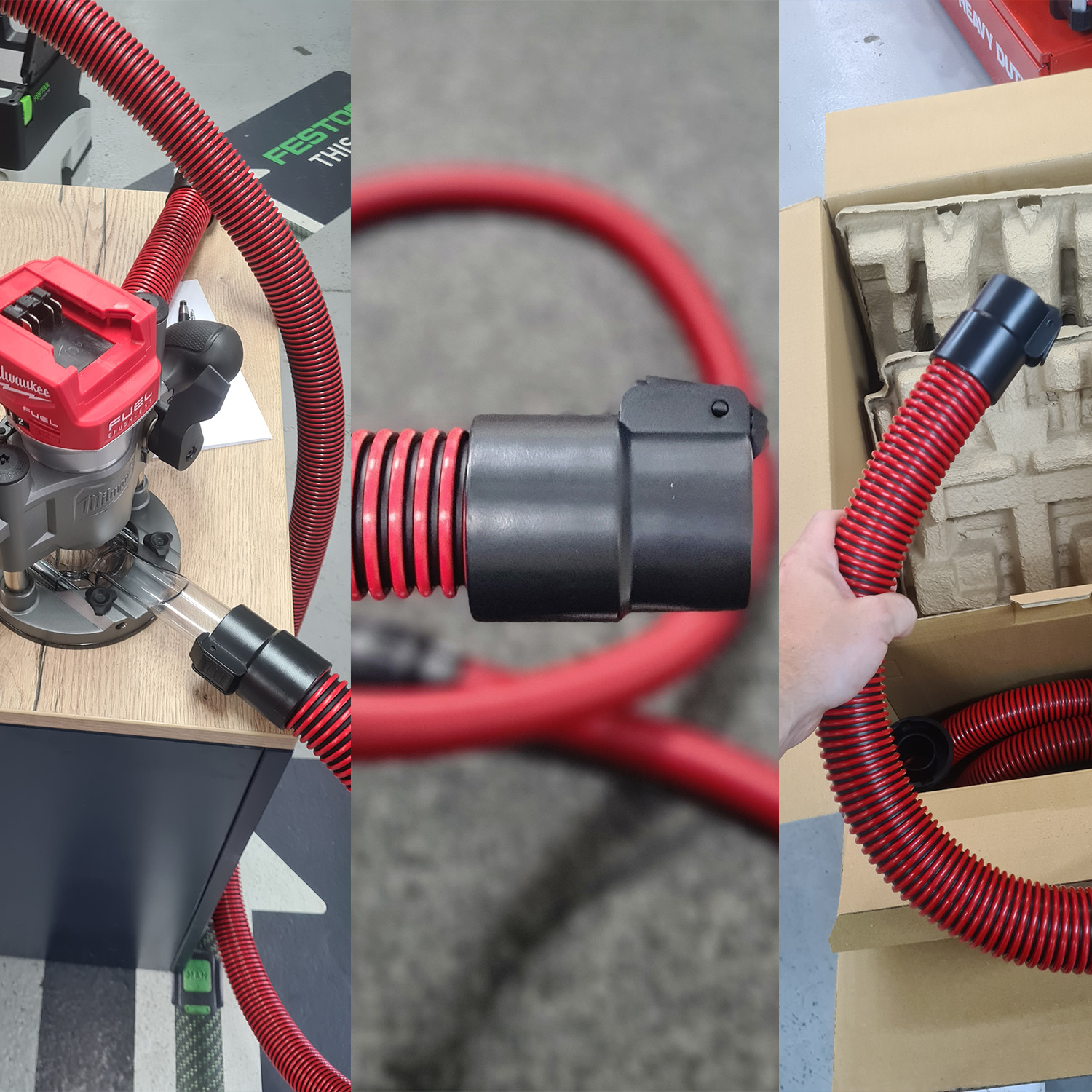

- Unique MultiFit tool adaptor nozzle fits dust extraction ports from many power tool brands, making connection easier and more secure for on tool extraction.

- Push to clean filter cleaning is a simple and effective way of using air pressure to thoroughly clean the filters and maintain air flow and extraction levels.

- Industrial quality floor tool set makes it possible to use the extractor as a workshop and site vacuum meeting M Class standards.

Protrade’s Verdict: Great for compatibility across multiple tool brands.

Metabo ASR35M ACP M Class Vacuum Dust Extractor

Having based the first commercially available cordless M Class extractor on the ASR35M, proves that Metabo are confident in this original corded offering. Boasting bombproof build quality and automatic filter cleaning means this machine is at home on the building site or workshop providing a reliable dust free solution whether you are sanding, sawing or wall chasing.

Key features:

- Automatic filter cleaning ensures maximum airflow during operation promoting safe and efficient working. The prevention of filter clogging through automatic cleaning also allows the use of PE dust bags for applications that generate lots of fine dust, for example – wall chasing and drywall sanding.

- Large container volume allows for the collection of high volumes of dust.

- Twin filters provide a large filtration surface area for effective extraction in continual use applications.

Protrade’s Verdict: A stalwart of the jobsite, this extractor is one of the most reliable on the market.

Festool CTM Midi GB 15L M Class Bluetooth Dust Extractor

Very high suction power and a compact design has made the Festool Midi incredibly popular with industrial contractors and artisans. The Sys-Dock provides a platform which can securely hold multiple Systainer boxes, turning the extractor into a trolley for your toolkit.

Bluetooth connectivity between the extractor and other Festool tools makes dust free working easy, by activating the extractor as soon as the power tool is started. If you are looking for a lightweight, high performance M Class extractor, the Festool Midi should definitely be on your shortlist.

Key features:

- Smooth suction hose glides over work surfaces preventing damage to the material and the hose itself. The RFID chip built into the rotating adaptor of the CTM Midi’s hose automatically recognises the hose diameter, eliminating the need for manual selection necessary for air flow monitoring.

- Sys-Dock and integrated hose storage allows Systainers to be stacked on top of the extractor and keeps the hose neatly tucked away when the extractor is not in use.

- Manual filter and bag cleaning helps to prevent a reduction in suction power and maximises bag fill.

Protrade’s Verdict: Feature packed and well thought out, the Festool CTM Midi is lightweight and compact making it ideal for use on the move.

Frequently Asked Questions

- Once I have used an M Class ‘on tool’ dust extractor, can I use a normal household vacuum to clean up when the work is finished?

Although a large amount of potentially harmful dust is removed by directly connecting a power tool to an extractor, any dust that is not captured remains a health risk if breathed in. The method of dust collection may be different, and the volume of dust is likely to be reduced but the type of dust remains the same. To be safe – always use an M Class for vacuuming duties after building work has stopped and clean up begins.

- What hose should I use with my extractor?

Fine dust travelling through the hose of an extractor can create a build-up of static within the hose. When this is discharged, it gives the feeling of a small electric shock which although harmless is unpleasant. Many M Class extractors come equipped with an antistatic hose which discharges the build-up immediately without you ever knowing. This isn’t the same for all M Class units though. In the case of the cordless Metabo ASR36-18 this uses an electrically conductive extraction hose that is specifically coded to suit the container, protecting the machines sophisticated electronics. Therefore, we always recommend using the manufacturers supplied hose to ensure compatibility.

- Can you use a long-life filter bag in an M-Class extractor?

No. Long-life filter bags are only intended for use with L class dusts.

- How often should I change the filter?

Changing the filter is dependent on how much dust it is exposed to. A filter inside an extractor, which is in continual heavy use, will need to be changed more often than one found in a rarely used machine. Checking the filter regularly for punctures and signs of clogging should be part of your routine extractor maintenance. As a minimum, we would suggest filters are replaced at least once a year.

- Why do dust extractors have variable suction speeds?

Reducing suction may seem a peculiar feature on a dust extractor, but it exists for a reason. When sanding large flat surfaces, reducing the extraction power can help to prevent the machine from being sucked to the surface which causes it to drag. This can have an adverse effect on surface finish, and in extreme cases it can cause premature bearing wear. When using accessories like a crevice tool on delicate materials such as fabrics or thin substrates, a reduction in suction power is preferable, helping to make the control of the nozzle easier and reduce the potential for damage to the workpiece. A reduction in noise also accompanies reduced suction power.

- Certain applications make it almost impossible to connect a dust extractor to my power tool but the job still needs to get done – how can I still work safely?

Adding on tool extraction should always be a first step to prevent the inhalation of harmful dust. However, this may not eliminate the need to wear suitable PPE such as a dust mask. Our preferred dust protection PPE is a PAPR unit – Powered Air Purifying Respirator. Products such as the Optrel Swiss Air unit offer higher levels of dust protection than dust masks, are extremely comfortable to wear and do not require face fit testing and even work with beards! Check out our previous blog on dust masks here: Five different dust mask types and when to use them

Final Thoughts

Hopefully, now you have read our blog on M-Class extractors you will realise the importance of protecting yourself from dust, be it generated by a power tool or simply left behind from refurbishment works.

Whilst the encouraging adoption of dust extraction is increasing, we still feel that many users are placing themselves at risk of serious illness by ignoring the unseen dangers of dust inhalation – which is avoidable.

Manufacturers are continually making extraction possible by the inclusion of dust ports on most power tools – therefore why not embrace a clean and safe working practise by using them!

Joint Managing Director, Protrade

Craig has over 30 years of experience at Protrade, working in various departments including sales, procurement, and marketing, and ultimately becoming Managing Director in 2008. Following the merger of Protrade and Joinery Fit-Out Supplies in 2018, Craig is now the joint MD of the company.