How To Keep Your Blades Sharp

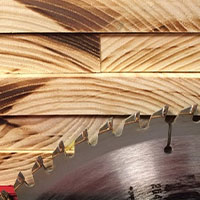

Power tools are only as good as the power tool accessories you put in them. I’ve lost count of the times we’ve received a burnt-out circular saw into our service centre, only to find the saw blade attached has blunt teeth. In some instances, even half of the tungsten carbide tips will be missing! It’s no surprise that trying to push a rotating ‘metal plate’ through a solid piece of timber might cause damage to the motor or mechanism that’s powering it.

Whether it’s a circular saw, plunge saw, mitre saw, table saw, jigsaw, chainsaw or even a planer, router or broaching machine, the blades or bits you put in them need to be sharp. That’s why we’ve put together our expert guide to keeping your power tool blades sharp, covering:

- Recognising when your blade is blunt

- Correct saw blade installation

- How to clean your saw blade

- Lubricating your blade

- Resharpening your blades

So let’s jump in.

How do I know when my blade is blunt?

It goes without saying that from the moment you start to use your tool accessory, it will start to wear. The longer you use it, the more it loses its edge, but at what point should you replace or resharpen it? If your blade starts to deteriorate during operation, there are four obvious signs you should be aware of:

- The blade starts to splinter or tear the wood. This often happens when cutting across the grain. As the blade exits the material, it can lift up small pieces, leaving a rough and unsatisfactory finish.

- The sound of the saw will change. You can often hear the sound of the saw’s motor labouring and you may also notice it getting warm. Any heat build-up in a motor will shorten it’s life. A trained ear can tell from the sound of the machine when the blade is getting blunt.

- The cutting speed noticeably decreases. A sharp blade will cut much faster than a blunt one. The more the blade

wears, the longer the cut takes. You will also notice the need to apply much more force to push the saw through the cut.

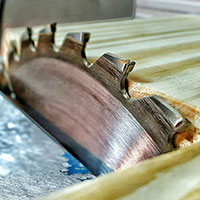

wears, the longer the cut takes. You will also notice the need to apply much more force to push the saw through the cut. - The rotational speed of the saw’s blade decreases. As it gets harder to cut through the wood material, the speed of the blade reduces causing friction build-up and scorch marks on both the blade and the workpiece. You may also sense a burning smell and observe smoke coming from the cutting area.

A blunt blade may not be the only reason for poor cutting performance

‘Dirty blades’ can also cause many of the issues mentioned above, so don’t automatically assume the cutting tool has lost its edge. Give the blade a visual inspection; chipped teeth or rounded edges are sure signs that your blade needs resharpening. Wood resin build-up around the teeth will also compromise cutting performance, but can easily be resolved with a good clean. Gently running your finger along the teeth’s edges, making light contact as they can be sharp, will also enable you to quickly identify whether the blade is blunt or simply requires basic maintenance.

Saw blade installation

I’m going to mention it as I have seen it happen before, but be sure you have put the blade on correctly and the teeth or cutting edges are pointing in the proper direction. Also be aware of the different kinds of circular saw blades for specific types of ‘power saws’, as the tooth rake or angle can vary for individual cutting actions. Incorrect installation or the wrong type of blade used may damage the workpiece and increase the risk of injury to the operator.

Simple tips for cleaning and maintaining your blades

If you regularly work with wood and board materials, it’s good practice to frequently clean your blades, so the resin or pitch doesn’t develop too much. An excessive build-up will reduce both the quality of cut as well as the life of the blade. For the sake of a few minutes every now and then, regular maintenance or cleaning will ensure optimum performance and maximum life.

How to clean your saw blade

- Collect all the tools required, such as a cleaning rag, an old toothbrush, a suitable degreaser and a drying cloth.

- If your blade is really dirty, brush or wipe down the blade to remove large areas of gunk, grease, dust, or wood chippings.

- Spray liberally with a degreasing solution and allow it to sit on the blade to penetrate the dirt for around 20 minutes. Avoid allowing the solution to evaporate by periodically giving the blade another spray.

- Agitate with a brush if there are any areas which need special attention.

- Rinse the blade under water with either running water or in a bucket or washing up bowl.

- Thoroughly dry your blade with the drying cloth.

- Apply lubricant to the whole blade.

Household cleaning solutions, including caustic oven cleaners, have been commonly used over the years to clean blades.

The blade manufacturers strongly advise not to use this type of product as it can affect the brazing around the carbide teeth, which could ultimately lead to the tungsten carbide teeth flying off. When a blade could be spinning at around 10,000 rpm – I think it’s wise to take the professional’s advice!

Less aggressive, solvent-free cleaners and degreasers, such as Maxitek All-Clean, would be much more advisable. Simply soak the blades for around 20 minutes, followed up with a firm wipe. For blades with excessive build-up, you may need to scrub gently – an old toothbrush is perfect for this job.

How do you lubricate a blade after cleaning?

After cleaning your blades, it’s important to properly rinse and completely dry them off. It’s highly likely that the cleaning process will have removed any lubrication from the blade’s surface, so it’s vital to re-lubricate after cleaning. This will enable the blade to produce cleaner cuts during use, and also protect the metal from potential rust build-up.

WD-40 is commonly used, or for even cleaner cutting results, I’d recommend using a specialist lubricant spray that leaves a very thin clear protective film over the face of the blade. The non-staining lubricant coating not only aids the cutting process, but also repels dirt, reducing future cleaning intervals.

Resharpening saw blades, cutters and bits

We’ve established that a poor cutting performance may not necessarily be down to the blade becoming blunt, but eventually any saw blade, cutter or bit will need to be resharpened.

Saw Blade Sharpening Service

I would advise using an expert Saw Doctor to carry out this task. It’s a precise art that requires specialist machinery to ensure a consistent finish and that an effective geometry is returned to the cutting edge of the resharpened item. Any damaged or missing teeth can also be replaced with new tungsten carbide tips, so your blade is almost as good as new.

“Protrade offers a comprehensive tool sharpening service, supported by a local dedicated Saw Doctor partner with years of experience and the latest state-of-the-art equipment”.

What is a Saw Doctor?

A Saw Doctor is capable of resharpening most types of saw blades, such as:

- Planer blades

- Router cutters

- Drill bits

- Chainsaws

- Premium handsaws

- Mortice chisels and chains

- Broaching cutters

- Guillotines

- Mower blades

Essentially, if it once had a sharp edge, there is a good chance a Saw Doctor can resharpen it. Rather than throwing worn blades or cutters in the bin, it’s much more cost effective to resharpen. Why not simply drop them into any Protrade Depot for a makeover?

throwing worn blades or cutters in the bin, it’s much more cost effective to resharpen. Why not simply drop them into any Protrade Depot for a makeover?

Tool And Saw Blade Sharpening Near Me

All depots stock a huge range of power tool consumables, so pick-up a brand-new replacement, allowing you to get on with the job, whilst the worn item is being rejuvenated. Turnaround times are typically between five and seven days, simply pick up at your convenience the next time you’re in!

Our longstanding relationship with a dedicated Saw Doctor partner and significant volumes from across our entire customer base, ensures the resharpening costs are extremely competitive and the end results are second to none.

For more information about our power tool repair and sharpening service, please contact Central Sales and Support or any Protrade Depot.

Joint Managing Director, Protrade

Craig has over 30 years of experience at Protrade, working in various departments including sales, procurement, and marketing, and ultimately becoming Managing Director in 2008. Following the merger of Protrade and Joinery Fit-Out Supplies in 2018, Craig is now the joint MD of the company.