Five different dust mask types & when to use them

In this article, we are going to discuss five different dust mask types, highlight the differences and explain where they can be used. It is important for users of respiratory protective equipment to understand that no dust mask will eliminate exposure entirely, and avoidance of the contaminant with extraction at source, should always be considered before relying on personal protective equipment.

The dust masks we’ll cover are:

- Face covering masks

- Disposable safety face masks

- Reusable non-replacement filter half mask

- Reusable half masks with replacement filters

- PAPR powered air purifying respirators

1. Face covering masks

Prior to March 2020 most of us had never experienced having to wear a safety mask. During the pandemic, wearing a face covering became a necessity and every day, people were donning a mask before walking into shops and restaurants or boarding public transport. There is, however, a significant difference between certified respirators, classed as Personal Protective Equipment (PPE), and the colourful face coverings or ‘surgical’ masks that we have become accustomed to throughout the Covid pandemic.

For clarity, respirators are designed to protect the wearer from exposure to airborne particulate hazards such as smoke, dust, viruses, aqueous and oil-based aerosols. Conversely, surgical masks – usually tested to EN 14683 – are designed to protect other people from the wearer, by preventing biological particles from being expelled into the environment. As for the ‘stylish’ fashion accessories we also see these days; they may help in combating Coronavirus to a degree but have little or no protection against dust particles or fumes.

View the face covering range here.

2. Disposable safety face masks

When it comes to initial outlay, disposable dust masks look to be the lowest cost solution for proper respiratory protection. For disposable respirators to work effectively, a tight seal upon the wearers face must be achieved. A face fit test will be necessary to ensure the mask is fitted correctly and provides adequate protection.

When it comes to initial outlay, disposable dust masks look to be the lowest cost solution for proper respiratory protection. For disposable respirators to work effectively, a tight seal upon the wearers face must be achieved. A face fit test will be necessary to ensure the mask is fitted correctly and provides adequate protection.

There are three classes of particulate filtration for disposable and semi-disposable safety masks. The table below shows the filtration rates and inward leakage. It is worth noting that the total inward leakage is a combination of face seal leakage, exhalation valve leakage – if the mask has a valve – and filter penetration.

Filtration levels applicable to disposable and semi disposable respirators

| Class | Min. Filter Efficiency | Max Inward Leakage | Total Protection |

| FFP1 | 80% | 22% | 58% |

| FFP2 | 94% | 8% | 86% |

| FFP3 | 99% | 2% | 97% |

P1 class respirators can be used in environments where the dust is non-toxic and non-fibrogenic.

P2 class respirators protect the user from harmful, fibrogenic liquid and solid particles, smoke, dust, bacteria and mould.

P3 class respirators offer the highest protection against toxic and harmful particles including some known carcinogens such as asbestos. P3 class respirators also offer protection against wood-based dusts and masonry containing silica.

You will notice a prefix FF before P1 – P3; this stands for ‘filtering facepiece’ and is only applied to disposable respirators. The WHO have suggested that a minimum of FFP2 filtration should be used for adequate protection against the Coronavirus.

Protrade choose to supply respirators with a minimum protection of FFP2 protection and in most cases, FFP3 is mandatory on most construction sites within the UK.

What do the markings mean on disposable face masks?

All reputable disposable dust masks are tested to the European standard EN 149:2001 + A1:2009 and have consistent markings – usually displayed on the front of the respirator.

All reputable disposable dust masks are tested to the European standard EN 149:2001 + A1:2009 and have consistent markings – usually displayed on the front of the respirator.

The example I have used here is a Valmy Cyrano face mask, starting from the top:

- CE is confirmation of CE marking and the 4-digit number that follows it is the Notified Body number.

- EN 149:2001 + A1:2009 is the European test standard.

- CYRANO is the brand of safety mask.

- FF (Filtering Facepiece) precedes the filtration level on all disposable masks.

- P3 is the filtration level – other types may be P2 or P1.

- NR means non-reusable; in other words, they should be discarded once removed. Some premium disposable masks may state R, which means they can be reused after being removed.

- D appears at the end if the mask has been Dolomite tested.

- Made in France is obviously the country of origin. It is not mandatory for this to be printed, but more reputable sources are often displayed to give the wearer confidence.

What is Dolomite testing for disposable safety masks?

Disposable respirator testing is usually conducted by spraying the mask with an aerosol formulation, typically sodium chloride and a paraffin oil. An optional test is often carried out by manufacturers, to demonstrate better breathing resistance in particularly dusty environments. This clogging test uses exceptionally fine dolomite dust, and if achieved, the mask will be stamped with the letter ‘D’.

What is the difference between valved and non-valved disposable safety masks?

Often confused with part of the filtering process, the valve on a dust mask is only used to expel air, helping to reduce heat build-up and condensation within. Exhalation valves are made from a wafer-thin rubber washer which work with the breathing pattern of the wearer. They open when blown against and shut tight when air is being sucked through the mask. Valves are a highly effective solution to wearer comfort in industrial environments – but they are not welcome in medical applications as the expelled air is unfiltered.

Often confused with part of the filtering process, the valve on a dust mask is only used to expel air, helping to reduce heat build-up and condensation within. Exhalation valves are made from a wafer-thin rubber washer which work with the breathing pattern of the wearer. They open when blown against and shut tight when air is being sucked through the mask. Valves are a highly effective solution to wearer comfort in industrial environments – but they are not welcome in medical applications as the expelled air is unfiltered.

There are, however, manufacturers such as Valmy, that have succeeded in making a non-valved FFP3 respirator, which offers the same breathing resistance as valved alternatives. Not having a valve reduces the weight of the mask and improves comfort. The manufacturers boldly declare in their marketing ‘you’ll forget you’re wearing it’! Another advantage of this design means the respirators can be used in both industrial and medical applications, which has resulted in the Valmy range of non-valved masks being awarded NHS approval.

What are disposable safety masks made from?

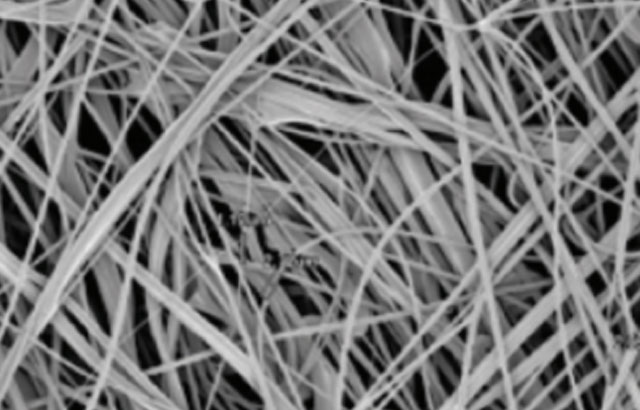

Specially designed, non-woven fabrics, provide the filtration material for disposable dust masks. The ultra-fine filaments are entangled to provide a filtering system, which allows air to pass through whilst trapping particles that are so small, they cannot be seen. The material is also electrostatically charged which attracts and holds onto these microscopic hazards. Up to the point where breathing becomes difficult, the filtration capability of a mask actually improves as it used. This is due to the filtration ‘mesh’ becoming finer as more particles are held within the fabric.

Although non-woven materials are lightweight and offer remarkable strength, comfort and filtering capability, the fibres used in mask production are typically made of polypropylene – a type of plastic. You can see from the highly magnified scan of melt-blown polypropylene, the fibres are layered on top of one another to form a non-woven cloth material. The long-term environmental effects of plastic pollution are well documented and unfortunately, disposable masks by their very nature, are single use. After just a few hours they are discarded and eventually end up in landfill, where they will remain for hundreds of years. There is also evidence to suggest that many find their way into our oceans. Understandably, masks used in medical procedures must be incinerated, but this too, contributes to pollution.

‘Researchers from University College London estimate that if every person in the UK used one single-use mask each day for a year, that would create 66,000 tonnes of plastic waste alone‘.

What are the pros and cons of disposable safety masks?

Pros:

- Lightweight and convenient

- Initial low cost

- Can be distributed amongst many operatives

Cons

- Face fit test required

- More difficult to get a good fit compared to reusable half masks

- High disposal rate makes them expensive over the long term, even reusable versions are only good for 2-3 shifts at best

- Common for the mask to move after initial fit, causing leakage and misting

- Once removed, it can be difficult to get a good seal thereafter

- Contribute to plastic pollution and shed microplastics into waterways

View the disposable safety mask range here.

3. Reusable non-replacement filter half mask

Reusable non-replaceable filter half masks are often referred to as ‘semi-disposable’ masks – tested to European standard EN 405. They are typically fitted with combination filters that offer protection from particulates as well as gases and vapours. The filters are bonded into the mask and cannot be replaced, which prevents contamination ingress through incorrect filter installation. The filter combination is pre-determined by the manufacturer, but there are different vapour/dust combinations depending on the hazard.

Reusable non-replaceable filter half masks are often referred to as ‘semi-disposable’ masks – tested to European standard EN 405. They are typically fitted with combination filters that offer protection from particulates as well as gases and vapours. The filters are bonded into the mask and cannot be replaced, which prevents contamination ingress through incorrect filter installation. The filter combination is pre-determined by the manufacturer, but there are different vapour/dust combinations depending on the hazard.

A common filter pairing is A2/P3. The P3 filter offers users the highest protection from dust particles and the A2 carbon filter protects against organic vapours found in spirit-based paints, many solvent cleaners and pourable contact adhesives. This particular filter combination is very popular in joinery and construction trades, as it protects against many hazards found in workshops and on the building site.

What is the working life of a non-replacement filter half mask?

As the filters are not replaceable, there is no obligation for companies to keep a care and maintenance log if the mask is disposed of after 28 days.

It is important for users to realise that the filters may not last 28 days in areas of high exposure, although reduced filter life in highly contaminated areas applies to all masks.

Using the mask beyond this period is possible providing a care and maintenance log is recorded. The mask is disposed of when the particulate filters become clogged and the gas filters saturated – usually detectable by increased breathing resistance or when the wearer can smell or taste the contaminant within the mask.

What are semi-disposable half masks made from?

Half masks are described as such because they only cover half of the face – the nose and mouth. They are typically made from elastomeric material such as soft, surgical rubber which enables the mask to provide an excellent seal on many face types. Indeed, a recent study conducted in a healthcare environment established that ‘an elastomeric respirator gave 60% higher filtration and a better seal when compared to a disposable respirator of the same filter efficiency’. All semi-disposable masks come with an exhalation valve.

Half masks are described as such because they only cover half of the face – the nose and mouth. They are typically made from elastomeric material such as soft, surgical rubber which enables the mask to provide an excellent seal on many face types. Indeed, a recent study conducted in a healthcare environment established that ‘an elastomeric respirator gave 60% higher filtration and a better seal when compared to a disposable respirator of the same filter efficiency’. All semi-disposable masks come with an exhalation valve.

Do semi-disposable half masks cost less than disposable masks?

Semi-disposable half masks can work out to be one of the most convenient, comfortable and lowest cost masks available, whilst offering excellent protection. Based on just twenty working days, a recent audit at a volume user of safety respirators, confirmed a 30% saving when using a semi-disposable half mask compared to a standard disposable mask. Both offered the same filtration efficiency, but the semi-disposable half mask also provided organic vapour protection as well.

What are the pros and cons of non-replaceable filter half masks?

Pros:

- Easier to obtain a tight face seal which is repeatable every time the mask is used

- Multiple hazard – off the shelf respiratory protection

- Many come with a re-sealable bag or container for safe storage

- No maintenance and records required

- Can be cleaned and disinfected according to manufacturer’s instructions

- Reduced plastic waste

- Very cost effective

Cons:

- Face fit test required

- Higher initial cost than a disposable mask

- Heavier than disposable respirators

- Once the filters have expired the whole mask needs to be replaced

View the reusable semi-disposable respirator range here.

4. Reusable half masks with replacement filters

Reusable half masks with replacement filters are tested to European standard EN 140. The ability to change the filters, depending on the protection required, makes this type of mask very flexible. There are many different types of gas and vapour filters that can be purchased individually.

Reusable half masks with replacement filters are tested to European standard EN 140. The ability to change the filters, depending on the protection required, makes this type of mask very flexible. There are many different types of gas and vapour filters that can be purchased individually.

If dust is an issue, dust pre-filters can be clicked onto the gas and vapour cartridge, thus forming a combination filter. In very dusty environments, this can be extremely cost effective as the pre-filters prevent premature clogging of the more expensive carbon filters underneath. If there is no gas and vapour risk, individual particulate filters are also available.

What is the working life of a reusable half mask with replacement filters?

Once the half-mask is purchased, it can last for a very long time with only the filters needing replacement. It is mandatory for a care and maintenance log to be kept, ensuring that there is no damage to the mask or filters which could reduce the masks’ effectiveness. As the half-mask could be in service for a long time, regular cleaning and disinfecting, in accordance with manufacturer’s instructions, is essential.

What are reusable half mask with replacement filters made from?

One could argue that a replaceable filter half-mask is identical to a semi-disposable mask, with the exception that the filters are replaceable. Whilst that is a fairly accurate description, because these masks need to have a method of attaching the filters – usually a screw thread or bayonet type fitting – they tend to be bulkier in size as the filters protrude further from the face.

One could argue that a replaceable filter half-mask is identical to a semi-disposable mask, with the exception that the filters are replaceable. Whilst that is a fairly accurate description, because these masks need to have a method of attaching the filters – usually a screw thread or bayonet type fitting – they tend to be bulkier in size as the filters protrude further from the face.

Do reusable half mask with replacement filters cost less than semi-disposable respirators?

Using replaceable filters makes this mask very low cost. If you are fastidious with cleaning and have a robust system ensuring maintenance is performed and records are kept, this is one of the lowest cost masks you can buy.

What are the pros and cons of reusable half mask with replacement filters?

Pros:

- Only filters need replacing

- Easier to obtain a tight face seal which is repeatable every time the mask is used

- Wide range of filters

- Less waste generated

- Very low cost over the long term

Cons:

- Care and maintenance record must be kept

- Regular cleaning required to ensure mask remains hygienic

- Face fit test required

- Can be bulky and heavy

View the reusable half masks with replacement filters range here.

5. PAPR powered air purifying respirators

Powered air purifying respirators, often abbreviated to PAPR, are tested to European standard EN 12941. Battery powered masks and powered respirators are other terms that are used in relation to PAPR systems. Like disposable masks and half mask respirators, there are different classes of particulate filtration associated with powered respirators.

Filtration levels applicable to PAPR powered air purifying respirators

| Class | Min. Filter Efficiency | Max Inward Leakage | Total Protection |

| TH1 | 99.99% | 10% | 89.99% |

| TH2 | 99.99% | 2% | 97.99% |

| TH3 | 99.99% | 0.2% | 99.79% |

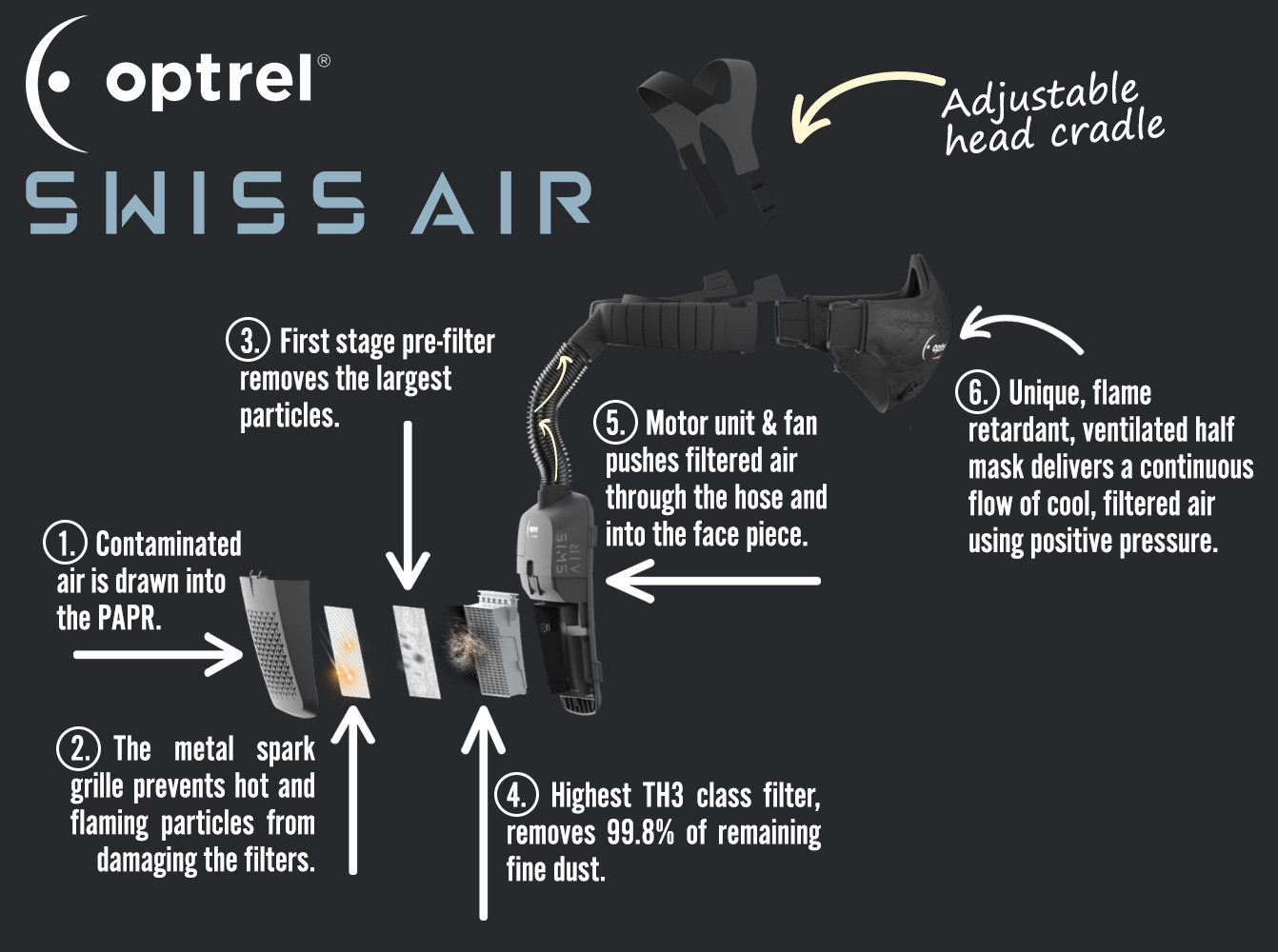

High-end manufacturers like Optrel, only develop powered respirators in class TH3, offering the highest particulate filtration level. When compared to an FFP3 disposable mask, which has 99% filtration with a 2% leakage – giving a total maximum protection of 97% – TH3 class powered respirators offer better total protection of 99.79% – with other significant benefits that we will come to. Organic vapour and gas filter cartridges are also available for some brands of PAPR systems.

What do PAPR powered air purifying respirator systems consist of?

Powered respirators, regardless of design or manufacturer, comprise of three essential components:

- Battery pack and motor unit – the battery powered motor draws air through the filter and passes clean air through to the headpiece or mask.

- Filter – removes contaminants from the air in the surrounding environment.

- Headpiece or half mask – provides a delivery method for the filtered air.

What types of PAPR powered air purifying respirators are available?

There are different configurations depending on the design, but the three main types are as follows:

Belt mounted battery, motor and filter unit – connected to a manufacturer approved head top such as a grinding visor, welding helmet or hood.

Belt mounted battery, motor and filter unit – connected to a manufacturer approved head top such as a grinding visor, welding helmet or hood.

Backpack mounted battery, motor unit and filter – connected to a half-mask. Non manufacturer specific additional PPE such as ear defenders, face shields, welding helmets and eyewear, can be worn in conjunction with this type of powered respirator.

Backpack mounted battery, motor unit and filter – connected to a half-mask. Non manufacturer specific additional PPE such as ear defenders, face shields, welding helmets and eyewear, can be worn in conjunction with this type of powered respirator.

Head top unit and face visor which contains the battery, motor unit and filter. These designs tend to be lower cost, compared to other more refined systems. With the total weight being on top of the users’ head, comfort and fatigue are a definite compromise.

Head top unit and face visor which contains the battery, motor unit and filter. These designs tend to be lower cost, compared to other more refined systems. With the total weight being on top of the users’ head, comfort and fatigue are a definite compromise.

How do PAPR powered air purifying respirator systems work?

Loose fitting battery powered respirators work on ‘positive pressure’. Having more pressure inside the mask than out, means particles, gases and vapours are pushed away by the continuous airflow and thus denied entry into the mask. This system of filtered air being delivered to the wearer, means a tight seal is not required and negates face fit testing – which necessitates being clean shaven. Beards, moustaches and even stubble can create channels which allow contaminants to enter the mask, so powered air purifying respirators are an ideal solution for operatives with facial hair.

No-one enjoys having to wear a mask despite the importance of using one. They feel unnatural, become hot, and make breathing more difficult as lung power is used to suck air through the filter material. A powered respirator overcomes most of the objections to wearing a mask. Agreed, they don’t feel natural, but not having a mask tightly pressed to your face is more comfortable and allows the respirator to be worn for extended periods. The air being blown through the mask also keeps the wearer cool and eliminates fogging of the face shield and other eyewear. The battery powered motor saves the lungs having to do any extra work so breathing is effortless.

Not all powered respirators systems work in the same way, so it is important to establish if the design is regarded as ‘loose fitting’ – therefore no fit test is required, or ‘tight fitting’ – where a fit test is required. Many designs will be ‘loose fitting’ as this is one of the key benefits of a PAPR system.

Do PAPR powered air purifying respirators cost less in the long term?

All PAPR systems have a high initial purchase price. However, not requiring a fit test, the incredible comfort in use and reduced filter disposal, can make them frugal over the long term. Do not also underestimate the feel-good factor either!

What are the pros and cons of PAPR powered air purifying respirators?

Pros:

- No face fit test required for loose-fitting systems

- Extended working periods

- Keeps operator cool

- Half mask versions can be combined with non-specific PPE

- Highest levels of filtration

- Perfect solution for wearers with facial hair

- Much less waste

- Low cost over the long term

Cons:

- High initial cost

View the PAPR powered air purifying respirators range here.

Summary – what is the best type of dust mask?

There are several factors to consider when purchasing a respirator, but ultimately it comes down to the protection that is required to complete the task in hand. Personal protective equipment is just that – personal! As we all come in different shapes and sizes, fit will also determine whether or not a particular mask is suitable. Finally, there’s the cost; quite often the masks which may look expensive initially, could end up saving you a significant amount of money… not forgetting the environmental gains.

It is essential that before selecting respiratory protection equipment, a full risk assessment is undertaken by a trained professional. No part of this article should be considered as a recommendation of Personal Protective Equipment for any of the applications referred to.

Joint Managing Director, Protrade

Craig has over 30 years of experience at Protrade, working in various departments including sales, procurement, and marketing, and ultimately becoming Managing Director in 2008. Following the merger of Protrade and Joinery Fit-Out Supplies in 2018, Craig is now the joint MD of the company.

Header image credit: Milwaukee Personal Protective Equipment